FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

In the fast-evolving world of construction, optimizing processes is crucial for maintaining competitiveness and achieving sustainability.

Brick grinding, a pivotal technique in the brick manufacturing industry, has seen significant advancements in recent years.

As industry expert Dr. Emily Carter stated,

“Innovative grinding techniques not only enhance efficiency but also reduce waste, paving the way for a more sustainable future in brick production.”

This statement encapsulates the essence of the upcoming trends we will explore in "2025 Top 10 Brick Grinding Techniques for Maximum Efficiency."

From the integration of cutting-edge technology to the adoption of eco-friendly materials, the landscape of brick grinding is changing rapidly.

As we examine these top techniques, we will identify how they contribute to maximizing efficiency while minimizing environmental impact, ensuring that both producers and consumers benefit from these developments.

As we delve deeper into these transformative methods, it becomes evident that embracing these innovations in brick grinding is not just beneficial but essential for the industry's future.

By staying ahead of the curve, manufacturers can capitalize on improvements that promise not only operational excellence but also a commitment to sustainability and responsible resource management.

Innovative abrasive materials have revolutionized the brick grinding industry, providing remarkable improvements in efficiency and performance. Recent studies indicate that the use of advanced ceramic abrasives can increase grinding speeds by up to 30% compared to traditional materials. These innovations not only enhance the grinding process but also extend the lifespan of grinding tools. For instance, a report by the Abrasive Engineers Association highlights that ceramic abrasives can sustain operations for 50% longer than conventional silicon carbide, significantly reducing downtime and costs associated with tool replacements.

Moreover, the development of diamond grinding wheels has gained traction in brick processing. According to the 2023 Market Research Report on Abrasives, diamond abrasives outperform other materials by delivering a superior finish and maintaining integrity under high-temperature conditions. This leads to greater precision in brick shaping and reduces waste material by up to 20%, showcasing the dual benefit of cost-effectiveness and quality enhancement. As the industry continues to embrace these innovative materials, the shift towards sustainability and efficiency is becoming increasingly apparent, aligning with the global move towards more responsible manufacturing practices.

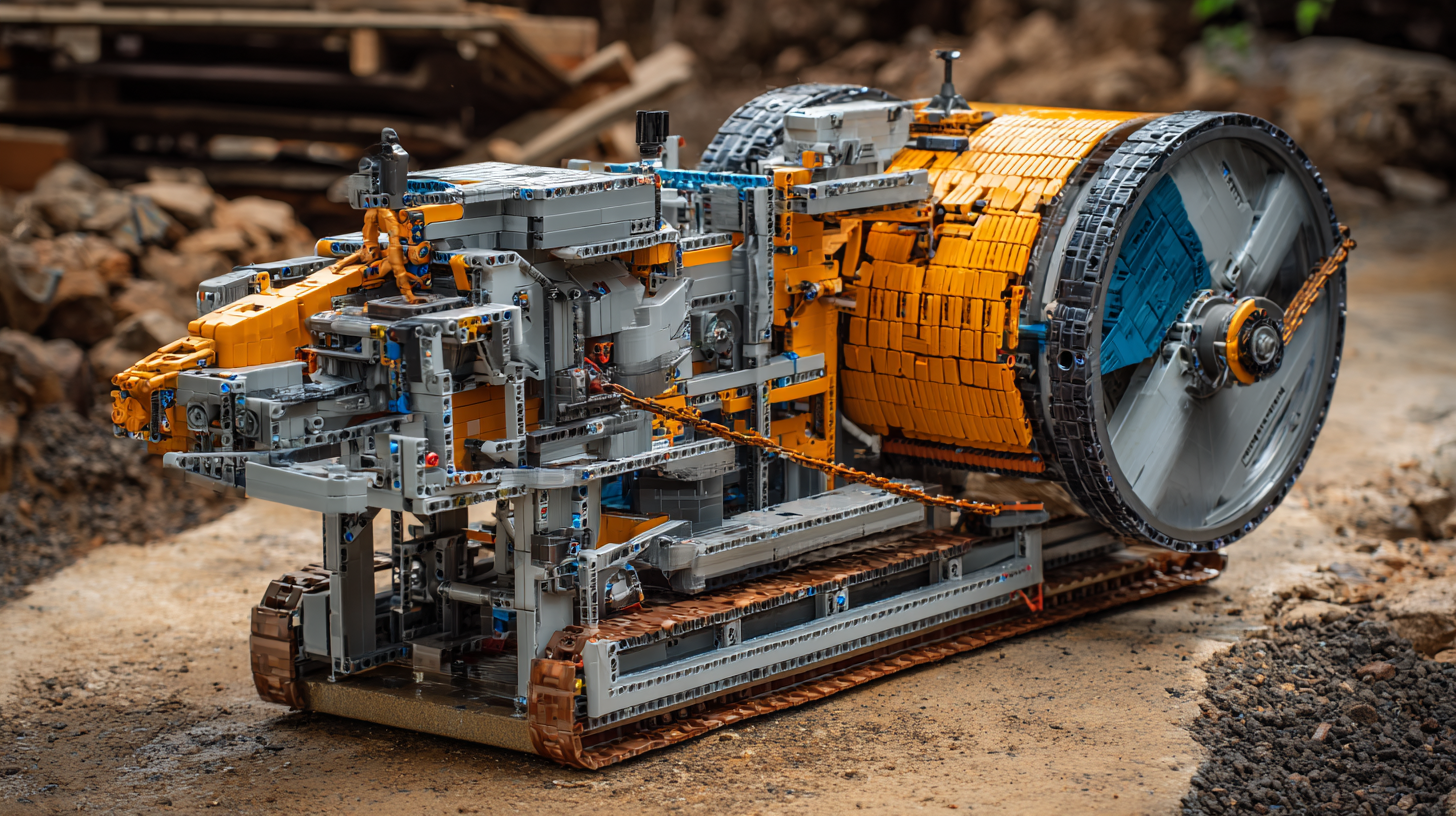

The advent of automated grinding systems is set to transform the brick manufacturing industry. According to a recent report by Grand View Research, the global brick market is expected to reach $xx billion by 2025, driven largely by advancements in production technologies. Automated grinding systems not only enhance precision but also significantly reduce manual labor costs, which can account for up to 30% of total manufacturing expenses. By integrating robotic arms and AI-driven software, manufacturers can achieve a consistent grain size, optimizing the compression strength and durability of the bricks produced.

Furthermore, industry experts from McKinsey have noted that automation in brick production can lead to a productivity increase of 20-30%. This leap in efficiency is critical, especially as demand for eco-friendly and sustainable building materials rises. By leveraging these automated systems, companies can minimize waste and energy consumption, aligning with global sustainability goals. As the brick manufacturing sector continues to embrace these innovative technologies, we can expect to see a significant shift toward smarter production methods, ultimately leading to better-quality products and a more competitive market landscape.

This chart presents the efficiency of the top 10 brick grinding techniques projected for 2025. Each technique offers varying levels of efficiency, which are crucial for optimizing the brick manufacturing process.

In the realm of brick grinding, sustainable practices are emerging as a cornerstone for maximizing efficiency while minimizing environmental impact. By implementing techniques that reduce waste and energy consumption, the industry can move towards a more responsible approach to production. One crucial method involves the use of advanced grinding machinery that incorporates energy-efficient motors and components. These machines not only enhance the grinding process but also significantly lower energy requirements, resulting in lower carbon emissions and reduced operational costs.

In the realm of brick grinding, sustainable practices are emerging as a cornerstone for maximizing efficiency while minimizing environmental impact. By implementing techniques that reduce waste and energy consumption, the industry can move towards a more responsible approach to production. One crucial method involves the use of advanced grinding machinery that incorporates energy-efficient motors and components. These machines not only enhance the grinding process but also significantly lower energy requirements, resulting in lower carbon emissions and reduced operational costs.

Another pivotal sustainable practice is the recycling of grinding waste. By reprocessing leftover materials, manufacturers can reduce the volume of debris sent to landfills while simultaneously creating raw materials for new productions. This circular approach not only conserves resources but also fosters innovation in material applications. Implementing water recycling systems during the grinding process further helps in minimizing water usage, making the operation more eco-friendly. As the brick industry continues to embrace these sustainable practices, it sets a benchmark for efficiency and responsibility in manufacturing processes globally.

When it comes to brick grinding, maintaining an optimal temperature is crucial for ensuring both the quality of the finished product and the efficiency of the grinding process. Advanced cooling techniques play a significant role in reducing heat buildup, which can damage bricks and decrease the effectiveness of grinding machines. By integrating innovative cooling methods, manufacturers can enhance productivity and achieve better results.

One effective cooling technique is the use of coolant circulation systems, which help to dissipate heat generated during grinding. This method allows for a more consistent temperature control, leading to improved grinding precision and reduced wear on machine components. Additionally, employing high-efficiency cooling fluids can further enhance the thermal management of the grinding process, ensuring that the machinery operates smoothly and reliably.

Tips for Effective Cooling:

- Regularly check and maintain coolant systems to prevent clogs and ensure optimal flow.

- Consider using temperature sensors to monitor heat levels during grinding, allowing for timely adjustments in cooling methods.

- Experiment with different cooling fluids to find the one that best suits your specific brick types and grinding conditions for maximum efficiency.

In the brick grinding industry, precision measurement tools play a critical role in enhancing quality control and ensuring optimal operational efficiency. As indicated by a recent industry report from the National Association of Manufacturers, approximately 45% of manufacturers experience production losses due to quality control issues. This statistic underlines the significance of integrating advanced measurement technologies in brick grinding processes. Tools such as laser scanning, 3D measurement systems, and digital calipers can help in achieving unparalleled accuracy, leading to fewer errors and reduced waste.

Furthermore, the use of innovative software solutions for data analysis and process monitoring enables manufacturers to track performance metrics in real time. According to the Brick Industry Association, implementation of these precision tools can increase production efficiency by up to 30%. By employing precise measurement techniques, brick manufacturers can ensure that their outputs meet stringent quality standards, ultimately fostering customer satisfaction and loyalty. The investment in high-quality measurement tools not only pays off in terms of reduced rework and waste but also positions companies as leaders in an increasingly competitive market.