FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

When embarking on a new DIY project or professional task, selecting the appropriate tools is crucial for achieving the best results, and one of the most essential tools in your toolkit is the drill. Among the various components that can greatly influence the success of your drilling endeavors are drill bits. The myriad types of drill bits available can make the selection process daunting, especially for those who may not be familiar with the specific needs of their project. Understanding the different materials, designs, and sizes of drill bits is vital, as each serves a distinct purpose and contributes uniquely to the efficiency and effectiveness of the drilling process. In this guide, we will explore key factors to consider when choosing the right drill bits for your project needs, empowering you to make informed decisions that enhance both precision and productivity.

When embarking on a drilling project, understanding the various types of drill bits available is crucial for achieving the best results. There are several common types of drill bits, each designed for specific materials and tasks. Twist bits are versatile and can be used on wood, metal, or plastic, while spade bits are ideal for larger holes in wood. For masonry projects, masonry bits, often made with a carbide tip, efficiently drill through bricks and concrete.

When embarking on a drilling project, understanding the various types of drill bits available is crucial for achieving the best results. There are several common types of drill bits, each designed for specific materials and tasks. Twist bits are versatile and can be used on wood, metal, or plastic, while spade bits are ideal for larger holes in wood. For masonry projects, masonry bits, often made with a carbide tip, efficiently drill through bricks and concrete.

Tips: When selecting a drill bit, consider the material you'll be working with. Using the wrong bit can not only impact performance but can also damage the workpiece. Additionally, keep your drill bits sharp. Dull bits require more effort and can lead to poor results. A good practice is to organize your bits in a way that makes accessing the right size easy, helping you work more efficiently.

For specialty projects, hole saws are perfect for creating large diameter openings, while step bits allow you to drill various sizes with one tool. For precision work, you might choose micro drill bits designed for small, intricate holes. By understanding these different types and their uses, you can choose the right bits that will enhance your project's success and craftsmanship.

When selecting drill bits for specific materials, it's essential to consider various factors that can influence performance and efficiency. One crucial aspect is the material being drilled. For instance, polycrystalline diamond composite (PDC) bits are often recommended for rock drilling due to their exceptional durability and heat resistance. Recent research highlights the importance of understanding how different rock types affect the temperature of PDC bits, which can impact their lifespan and drilling efficacy. High-performance bits should be chosen based on their ability to withstand the specific conditions posed by the material.

Another key factor is the operational parameters of the drilling rig, including spindle speed and feed rate. For example, studies have shown that variations in these parameters significantly affect torque and thrust force, leading to variations in surface roughness and temperature during machining processes. Using the right drill bit in conjunction with optimized drilling conditions can drastically improve project outcomes. Therefore, it is beneficial for users to reference industry-specific reports and studies when choosing drill bits to ensure they meet the specific demands of their projects.

When embarking on a drilling project, selecting the appropriate drill bits is crucial to meet specific project requirements, primarily concerning size and length. According to a recent industry report by the National Hardware Association, using the right drill bit can enhance efficiency by up to 25%. Understanding the size of the hole you need to create is fundamental. For example, standard sizes like 1/8", 1/4", and 3/8" are often used in both professional and DIY settings, depending on the materials that need drilling.

Additionally, the length of the drill bit plays a significant role in material penetration. A standard length bit is sufficient for most applications, but when working with thicker materials, opting for longer bits ensures a clean and precise hole without requiring excessive pressure.

**Tips:** Always measure the thickness of the material before selecting your drill bit. If unsure, start with a smaller bit to gauge the material's response. Lastly, consider using a step bit for varied hole sizes within the same project, providing versatility and efficiency in one tool.

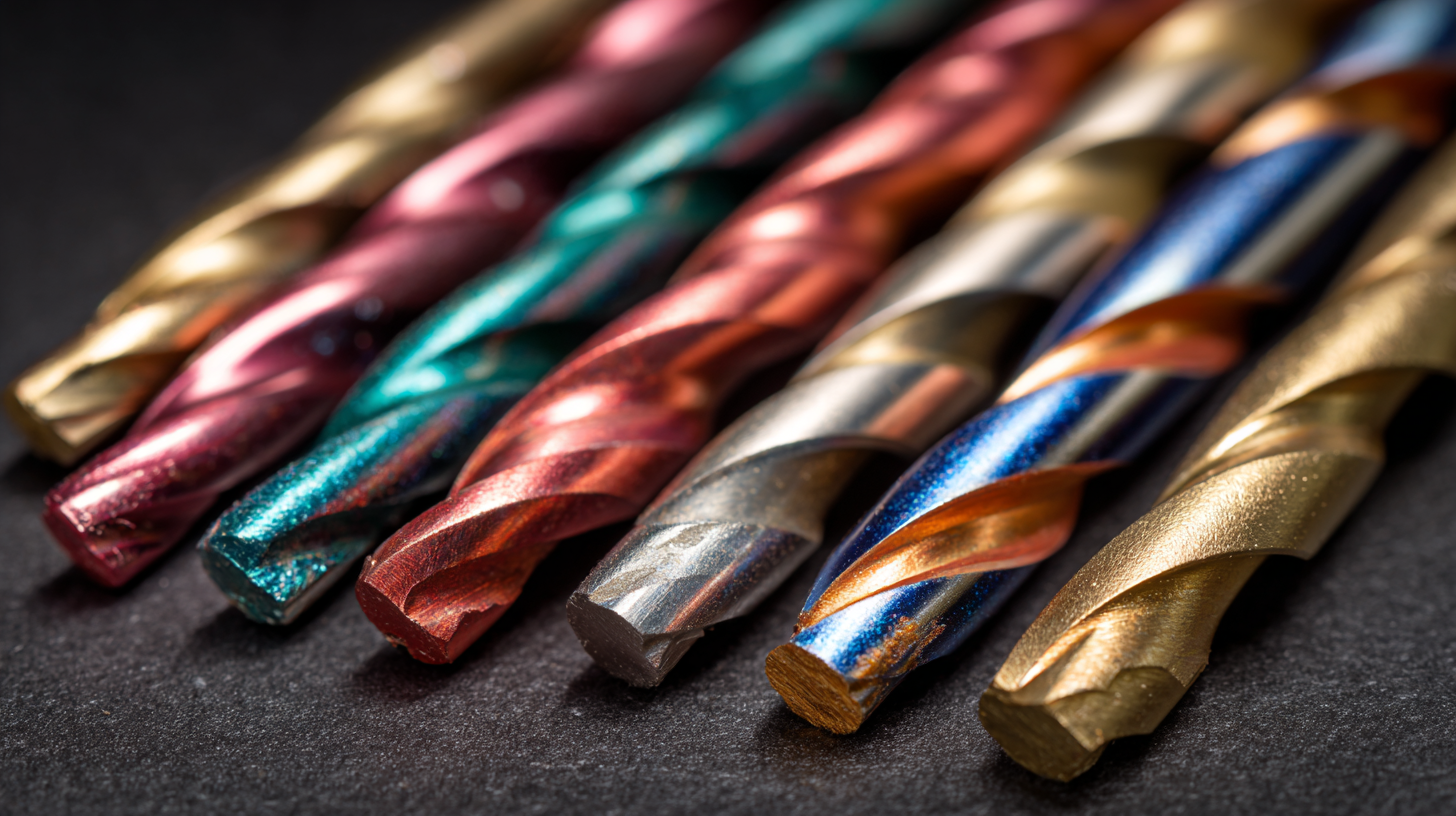

When selecting drill bits for a project, the quality of the materials and coatings greatly influences performance and longevity. High-quality drill bits are typically made from materials such as high-speed steel (HSS), cobalt, or carbide, each offering distinct advantages. HSS bits are versatile and suitable for various applications, while cobalt bits are designed for tougher materials and prolonged use in high-temperature conditions. Carbide bits, on the other hand, are incredibly durable and ideal for drilling into hard materials like masonry or concrete.

In addition to the base material, the coating on a drill bit can enhance its efficiency and lifespan. Common coatings include titanium nitride (TiN), which reduces friction and increases surface hardness, or black oxide coatings that help resist corrosion. These coatings not only extend the life of the drill bits but also improve their cutting performance. Choosing the right combination of material and coating ensures that the drill bits will provide optimal results for your specific project needs, whether for wood, metal, or other materials.

Maintaining and storing your drill bits effectively can significantly extend their lifespan and enhance your project efficiency. To keep your drill bits in optimal condition, regularly clean them after use. Remove any debris or residue by using a brush or cloth, ensuring that they remain free from rust or corrosion. For bits that have seen extensive use, sharpen them carefully with a proper sharpening tool. This will help maintain their cutting edge, making your drilling tasks more effective and reducing strain on your tools.

Proper storage is equally crucial. Organize your drill bits in a designated case or holder that keeps them separated and secure, preventing them from dulling or damaging each other. You can also use magnetic strips or pegboards to keep them visible and easily accessible. Ensure that the storage area is dry and free from excessive moisture to avoid rust. By taking these steps in maintenance and storage, you'll not only protect your investment but also prepare your drill bits for a variety of projects with ease and confidence.

This chart illustrates the optimal drill bit sizes measured in millimeters for various materials. Selecting the correct drill bit is crucial for the quality of your project, ensuring efficiency and effectiveness in drilling tasks.