FREE SHIPPING ON ALL BUSHNELL PRODUCTS

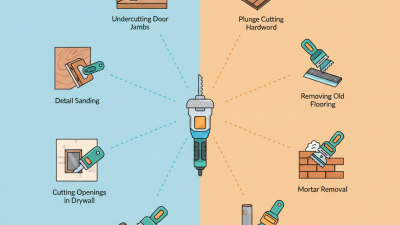

Leave Your Message

Choosing the right Brick Cutting Blade is crucial for the success of your projects. A suitable blade can determine the quality of your cuts and the speed of your work. However, many factors come into play when selecting the perfect blade. It's not a one-size-fits-all solution.

Consider the material of the brick. Different bricks require different cutting techniques. You must also think about the power tool you’ll use. Some blades fit specific saws, and compatibility matters. Remember to evaluate the blade’s size and thickness. Often, the best choice is not immediately clear.

Quality can vary significantly among brands. Investing time to research will save you trouble later. Look for user reviews and product details. It’s also wise to reflect on past experiences. Did you struggle with the last project because of a poor blade choice? Taking these aspects into account will lead to better decisions and project outcomes.

When selecting a brick cutting blade, understanding the types available is crucial. There are several types on the market. Each type has specific uses and performance characteristics that suit different projects. For example, diamond blades are popular for their durability and precision. They offer excellent cutting speed and longevity, making them a go-to choice for professionals. According to a 2022 industry report, diamond blades account for over 40% of the market due to their efficiency.

Another type is carbide-tipped blades. These are generally more affordable than diamond blades. They provide decent performance for smaller projects. However, they may wear out quicker, especially on harder materials. An analysis showed that while carbide blades represent about 25% of the market, users often report a need for frequent replacements, creating extra costs over time.

Wet-cutting and dry-cutting blades also play significant roles. Wet-cutting blades reduce dust and enhance efficiency by cooling the blade during operation. In contrast, dry-cutting blades are more portable. However, they can generate substantial dust, which some users find problematic. A survey found that 35% of users prefer wet-cutting for indoor projects due to cleaner results. Each type has advantages and drawbacks, making it essential to evaluate your specific project needs before making a choice.

Choosing the right brick cutting blade is crucial for your projects. It directly impacts performance and efficiency. Consider the material of the blade. Diamond blades are popular for their durability. However, not all diamond blades are the same. Some are designed for dry cutting, while others work better with water. Check the specifications to ensure it fits your needs.

Next, think about the blade's size. Larger blades can cut deeper, but they may not fit in tight spaces. For small projects, a compact blade might suffice. Also, consider the tooth design. Blades with more teeth provide a smoother cut but can be slower. Fewer teeth can offer faster cuts with more roughness.

Reflect on the straightness of your cuts too. Sometimes, the right blade still leads to uneven cutting. This can be frustrating. Ensure your cutting technique is also good. A poor angle can ruin your project completely. Take your time and practice, even with the best blade. The right choice requires careful consideration, but it's part of the learning process.

When selecting a cutting blade for brick projects, it’s essential to consider blade composition. The materials used in a blade directly impact its performance. Common materials include diamond, carbide, and high-speed steel. Diamond blades are popular for their durability. They can handle tough jobs with ease. However, they may be overkill for smaller tasks.

Carbide blades also offer good durability. They are suitable for various masonry jobs. However, they might wear out more quickly than diamond blades. High-speed steel blades are usually less expensive. They can be efficient but are not as durable as the other options. Each type has its strengths and weaknesses.

While choosing a blade, reflect on your project’s specific needs. Consider the brick type and the cutting frequency. A good blade may still struggle if it's not well-suited. This can lead to frustrations and extra costs. Evaluate how often you'll use the blade to make a better choice. Balancing durability and cost is crucial. A perfect blade may not exist, but the right one for your task surely can.

| Blade Type | Material Composition | Typical Use | Durability Rating | Cost Range |

|---|---|---|---|---|

| Diamond Blade | High-quality diamond segments | General brick cutting | High | $50 - $150 |

| Wet Cutting Blade | Diamond with special bonding agent | Limit dust, minimize heat | Medium | $40 - $120 |

| Segmented Blade | Steel core with segmented diamond rim | Fast cutting through bricks | Medium | $30 - $100 |

| Turbo Blade | Continuous diamond rim with turbo design | Precision cutting | High | $70 - $200 |

| Masonry Blade | Hard abrasive material | Chipping bricks | Low | $15 - $50 |

Choosing the right blade size is crucial for effective brick cutting. You need to know the dimensions of the bricks you will work with. Common sizes include 4-inch, 6-inch, and 10-inch blades. A blade that is too large may be unwieldy. A smaller blade might not create clean cuts. Take the time to measure your bricks carefully before making a decision.

Compatibility with your cutting tool is another important factor. Not all blades fit every tool. Check the arbor size and mounting options. Incompatible blades can cause safety issues. If you are unsure, consult your tool's manual for guidance. Having the correct setup makes your project smoother. Think about the type of cuts you need. Straight cuts require a different blade than angled cuts. Small details matter.

Wide blades might cut faster, but they can fracture bricks if not handled properly. Sometimes, it may be better to use a thinner blade for precision. Trial and error can lead to unexpected results. Don't rush the process; take your time to experiment. You can learn from mistakes, refining your choice as you go. A careful selection leads to better outcomes.

Maintaining your brick cutting blade is essential for longevity. Regular cleaning is vital to remove dust and debris that accumulate during use. A clean blade cuts more efficiently. Every few uses, take time to inspect the blade for wear. Look for signs of chipping or dull edges. Noticing these issues early can prevent deeper damage.

Using the right cutting technique also plays a role in the maintenance of your blade. Pressing too hard can lead to premature wear. Instead, allow the tool to do the work. Keep the blade cool during use. Overheating can warp the blade. If you notice a change in performance, it might be time to reassess your technique.

Lubrication can be beneficial, but moderation is key. Too much lubricant can attract dirt. A light application keeps things running smoothly. Finally, store your blade properly. Avoid damp areas that can lead to rust. A simple, dry place ensures your tools remain in top condition for future projects. Making these small adjustments can significantly enhance your blade's lifespan.