FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Choosing the right brick cutting blade is a pivotal decision that can significantly impact the efficiency and quality of masonry projects. According to a report by the Freedonia Group, the demand for cutting tools, including specialized blades for construction materials, is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025. The right blade not only enhances cutting speed but also ensures cleaner cuts, leading to less waste and a more professional finish.

Moreover, industry studies have shown that improper blade selection can lead to increased material costs, project delays, and even safety hazards on job sites. With a vast array of options available, ranging from diamond blades to segmented options, understanding the specifications and applications of a brick cutting blade becomes crucial. Selecting a blade tailored to the specific type of brick and project requirements can improve durability and performance, making it essential for contractors and DIY enthusiasts alike to invest time in choosing the optimal blade for their needs.

When it comes to brick cutting, selecting the appropriate blade can significantly impact the quality and efficiency of your projects. There are several types of brick cutting blades available, each designed for specific applications and materials. Understanding these different blade types is crucial for achieving optimal results.

For instance, diamond blades are favored for their durability and precision. According to industry reports, diamond blades can last up to five times longer than standard steel blades, making them a cost-effective choice for heavy-duty cutting tasks.

In contrast, circular blades, often made from high-speed steel, are ideal for smaller jobs and can provide a clean cut at a lower cost. A study by the American National Standards Institute highlighted that using the right type of blade can reduce cutting time by as much as 30%, thereby enhancing overall productivity on-site. Additionally, specialized blades designed for specific materials, such as porous or hard-fired bricks, contribute further to the efficiency and finish of the work. This variety emphasizes the importance of considering the material properties and project requirements when choosing a cutting blade.

When selecting a brick cutting blade, it is crucial to consider several key factors to ensure efficiency and quality in your projects. Firstly, the material and type of blade are paramount.

Diamond blades are often preferred for their durability and cutting performance on hard materials like brick, providing clean cuts and minimizing chipping. Additionally, the thickness of the blade can impact the cutting speed and precision; a thinner blade can offer quicker cuts but may require more careful handling to avoid breakage.

Another vital factor is the intended use of the blade. If you plan to cut bricks frequently, a blade designed for high-performance cutting, such as those with a segmented or turbo design, may be necessary. Furthermore, the size of the blade needs to match your cutting tool, ensuring compatibility to achieve optimal results. It's also essential to consider the cutting conditions, such as whether you will be working wet or dry, as this can influence the choice of blade and its lifespan.

By paying attention to these factors, you can select a brick cutting blade that meets the specific demands of your project, enhancing both safety and effectiveness.

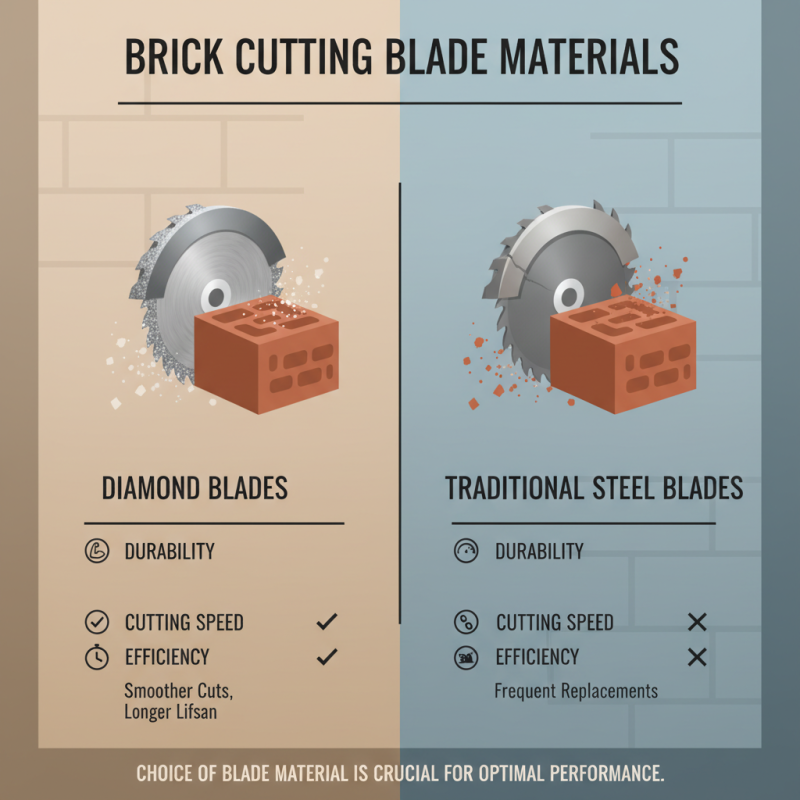

When it comes to cutting bricks, the choice of blade material is crucial for achieving optimal performance. Different materials can significantly influence the blade’s durability, cutting speed, and overall efficiency. For instance, diamond blades, known for their hardness, are highly effective for slicing through tough brick surfaces with precision. The intrinsic properties of diamond allow for smoother cuts and a longer lifespan compared to traditional steel blades, reducing the need for frequent replacements.

On the other hand, carbide-tipped blades present an excellent balance of cost and performance. These blades, made with a composite of steel and carbide, offer a good cutting performance on various materials while being more economical than their diamond counterparts. Understanding the specific project requirements and the types of bricks being used is essential when deciding on the blade material; this ensures that the right tool is chosen for the job, minimizing wear and tear while maximizing output efficiency. The material of the blade can ultimately determine the success of any brick-related project.

When it comes to cutting bricks, the size of the blade plays a crucial role in determining both efficiency and precision. Larger blades often allow for deeper cuts in a single pass, which can be particularly beneficial for thicker bricks. However, using a blade that is too large for the task at hand may lead to handling difficulties and decreased control over the cutting process. Conversely, smaller blades provide greater maneuverability and can be ideal for detailed work or intricate patterns but may require multiple passes to achieve the desired depth.

Tips: Always match the blade size to the type of brick and the specific demands of your project. For standard brick sizes, a blade diameter between 4 to 7 inches often works best. If you’re dealing with larger, thicker bricks, consider blades that exceed 10 inches in diameter to optimize efficiency.

Furthermore, the type of cuts you plan to make should inform your choice of blade size. For straight, long cuts, a larger blade can increase speed and reduce the number of passes needed. If your project entails curved or detailed cuts, then opting for a smaller blade will enhance precision. Understanding these dynamics will lead to smoother cutting processes and better results on your brickwork projects.

| Blade Size (Diameter) | Cutting Depth (inches) | Cutting Speed (ft/min) | Material Type | Durability Rating (hours) |

|---|---|---|---|---|

| 12 inches | 3 | 50 | Ceramic | 15 |

| 14 inches | 4 | 60 | Concrete | 20 |

| 16 inches | 5 | 70 | Brick | 25 |

| 18 inches | 6 | 80 | Masonry | 30 |

Maintaining your brick cutting blade is crucial for ensuring its longevity and optimal performance. First and foremost, regular cleaning is essential. After each use, remove any debris or dust that may have accumulated on the blade. This not only prevents buildup that can affect the blade's efficiency but also minimizes the risk of corrosion. A simple brush or cloth can be used to wipe down the blade, keeping it free from any particulate matter that might interfere with its cutting capabilities.

Another key aspect of blade maintenance is monitoring its sharpness. Dull blades can cause increased friction, leading to overheating and potential damage. To maintain sharpness, consider using a sharpening tool designed for diamond blades or have the blade professionally sharpened when it shows signs of wear. Furthermore, it’s important to store the blade in a dry, safe place, away from direct contact with other tools that could cause nicks or chips. By following these simple tips, you can significantly extend the life of your brick cutting blade and ensure it remains effective for your future projects.