FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

When embarking on any cutting project, selecting the appropriate Circular Saw Blade is crucial to achieving precision and efficiency. Industry expert John Smith, a seasoned professional with over two decades of experience in power tools, emphasizes the importance of choosing the right blade: “The efficiency and outcome of your project hinge on the blade you select; a well-chosen Circular Saw Blade can make all the difference.” With a plethora of options available, understanding the specifications and applications of various blades can be overwhelming for both novice and seasoned woodworkers alike.

The Circular Saw Blade serves as the heart of the saw, directly influencing the quality of the cut and the effectiveness of the tool. From fine crosscuts to aggressive ripping, different blades are engineered for specific materials and cutting tasks. In this guide, we will explore the essential factors to consider when choosing a Circular Saw Blade, including tooth design, material type, and blade diameter, ensuring that your cutting projects are successful and up to professional standards. By equipping yourself with the right information, you can make an informed decision that enhances your craftsmanship and project outcomes.

When embarking on a cutting project, understanding the different types of circular saw blades is crucial for achieving optimal results. Each blade is designed for specific materials and cuts, making it essential to select the right one. For instance, rip blades are engineered with fewer teeth and larger gullets, allowing for fast cuts along the grain of wood. This makes them ideal for ripping lumber quickly, whereas crosscut blades feature more teeth to create cleaner, precise cuts across the grain, perfect for finishing work.

Moreover, specialty blades are available for various materials beyond wood. For example, metal cutting blades often have a unique tooth design that enables them to handle harder materials, reducing the risk of damage to both the blade and the workpiece. Similarly, diamond blades are used for cutting concrete and masonry, as they can withstand high temperatures and abrasive materials. By recognizing the specific characteristics and intended uses of each blade type, users can ensure that their circular saw provides efficient and effective cutting, tailored to their project's needs.

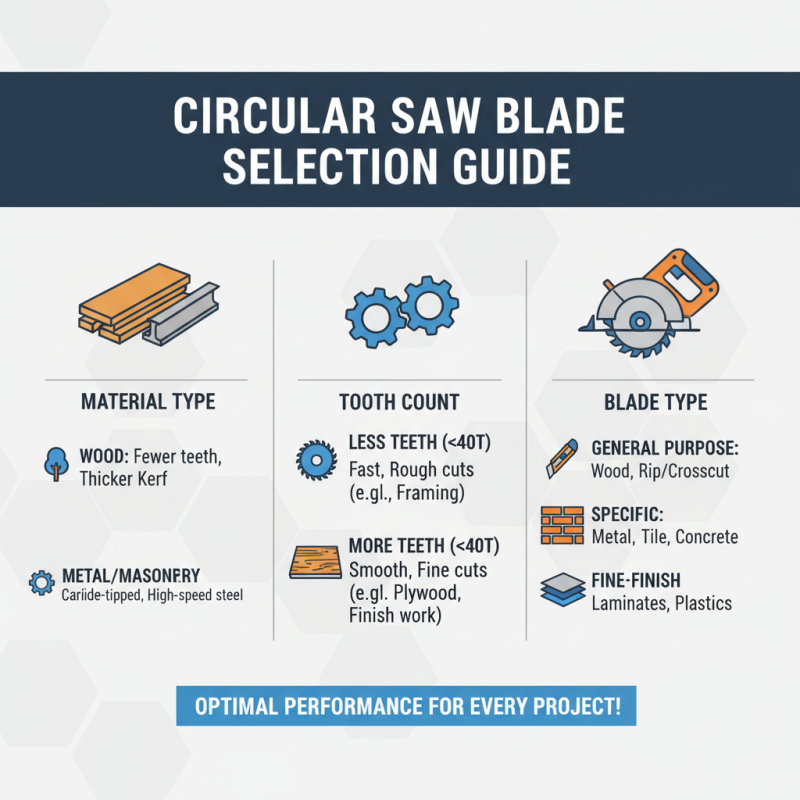

When choosing the right circular saw blade for your cutting projects, several key factors should be taken into consideration to ensure optimal performance. One critical factor is the type of material you will be cutting. Blades designed for wood often feature fewer teeth and a thicker kerf to manage the material's density, while blades intended for metal or masonry are typically constructed from high-speed steel or carbide-tipped to withstand tougher conditions. Understanding the context of your project will help determine the appropriate blade type.

Another important consideration is the tooth count of the blade. Blades with fewer teeth provide faster cuts but tend to produce rougher edges, making them suitable for quick cuts in soft materials. Conversely, blades with a higher tooth count yield smoother finishes, which is ideal for precision work or cutting hardwoods and laminates. Additionally, the tooth geometry affects how the blade interacts with the material. For example, flat-top teeth excel in cross-cutting while alternate top bevel teeth enhance ripping capabilities. Taking these factors into account will guide you in selecting a circular saw blade that meets your specific cutting needs.

When it comes to selecting a circular saw blade, the material from which the blade is made plays a crucial role in its performance and suitability for specific cutting projects. The most common materials for circular saw blades include high-carbon steel (HCS), high-speed steel (HSS), carbide-tipped, and diamond blades. According to industry reports, carbide-tipped blades are favored for their durability and ability to maintain sharpness over extended periods. These blades contain tungsten carbide tips, making them highly effective for cutting hardwood, composites, and even metal.

On the other hand, high-carbon steel blades are cost-effective and provide a good option for light-duty cutting tasks or softwoods. However, they lack the longevity and cutting precision of carbide-tipped or diamond blades. Data from the Association of Woodworking & Furnishings Suppliers indicates that switching to a carbide-tipped blade can increase cutting efficiency by approximately 30% due to reduced wear and heat buildup. For specialized applications like concrete cutting, diamond blades are the ideal choice, as they feature segments embedded with diamond particles, ensuring superior performance in tough materials without significant blade degradation.

Ultimately, the choice of blade material should align with the specific requirements of your cutting projects, balancing performance, durability, and cost-effectiveness. Understanding the inherent properties of each material can significantly enhance the quality of your work and help you achieve professional results every time.

| Blade Material | Best For | Advantages | Disadvantages |

|---|---|---|---|

| High-Speed Steel (HSS) | Wood and Soft Materials | Good durability and affordable | Can dull quickly on hard materials |

| Carbide-Tipped | Wood, MDF, and Laminates | Long lasting and versatile | More expensive than HSS |

| Diamond | Concrete, Masonry, and Tile | Extremely durable for hard materials | High initial cost and specific use |

| Aluminum | Aluminum and Non-ferrous Metals | Clean cuts and less burr formation | Limited use compared to other materials |

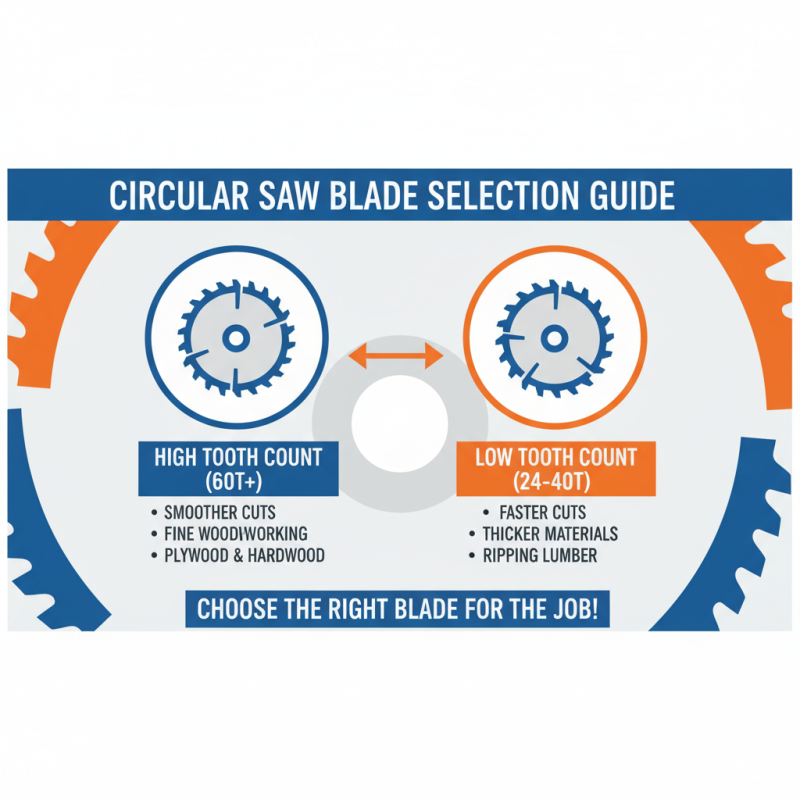

When selecting a circular saw blade, the tooth count and configuration play a pivotal role in determining the overall cutting performance. Blades with a higher tooth count generally produce smoother cuts, making them ideal for fine woodworking and applications that require precision. For instance, a blade with 60 teeth can offer excellent finish cuts in plywood and hardwood. Conversely, blades with fewer teeth, such as 24 or 40, are designed for faster cuts through thicker materials, allowing for expedited ripping tasks without focusing on finish quality.

The configuration of the teeth also significantly influences how well the blade performs for different cutting tasks. Flat-top grind (FTG) teeth are excellent for ripping lumber, as they efficiently remove material in a straight path. On the other hand, alternate top bevel (ATB) teeth are optimized for cross-cutting, providing cleaner edges by slicing through the grain rather than tearing it. A combination tooth (combination) blade, featuring both ATB and FTG teeth, offers versatility for users who engage in diverse cutting projects. By understanding how tooth count and configuration affect cutting outcomes, one can make informed choices that enhance the efficiency and quality of their work.

When selecting the right circular saw blade for your specific cutting project, it’s vital to consider the material you will be working with. Different materials require different types of blades to achieve optimal results. For instance, a blade designed for cutting wood typically features fewer teeth, which allows for faster cuts and efficient removal of sawdust. According to a report by the National Wood Flooring Association, using the correct blade can reduce cutting time by up to 30%, enhancing overall productivity in woodworking projects.

On the other hand, if your project involves cutting metal or masonry, a blade with a higher tooth count and specialized materials, such as carbide-tipped teeth, is essential. The cutting speed and quality of the finish can be dramatically impacted by the blade selection; as per data from the Metalworking Business Network, using the appropriate blade can result in an increase of up to 20% in cutting efficiency, as well as decreased wear and tear on tools. In summary, understanding the specific requirements of your cutting project, including material type and desired cutting efficiency, is fundamental for selecting the right circular saw blade and ensuring seamless performance throughout the job.