FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

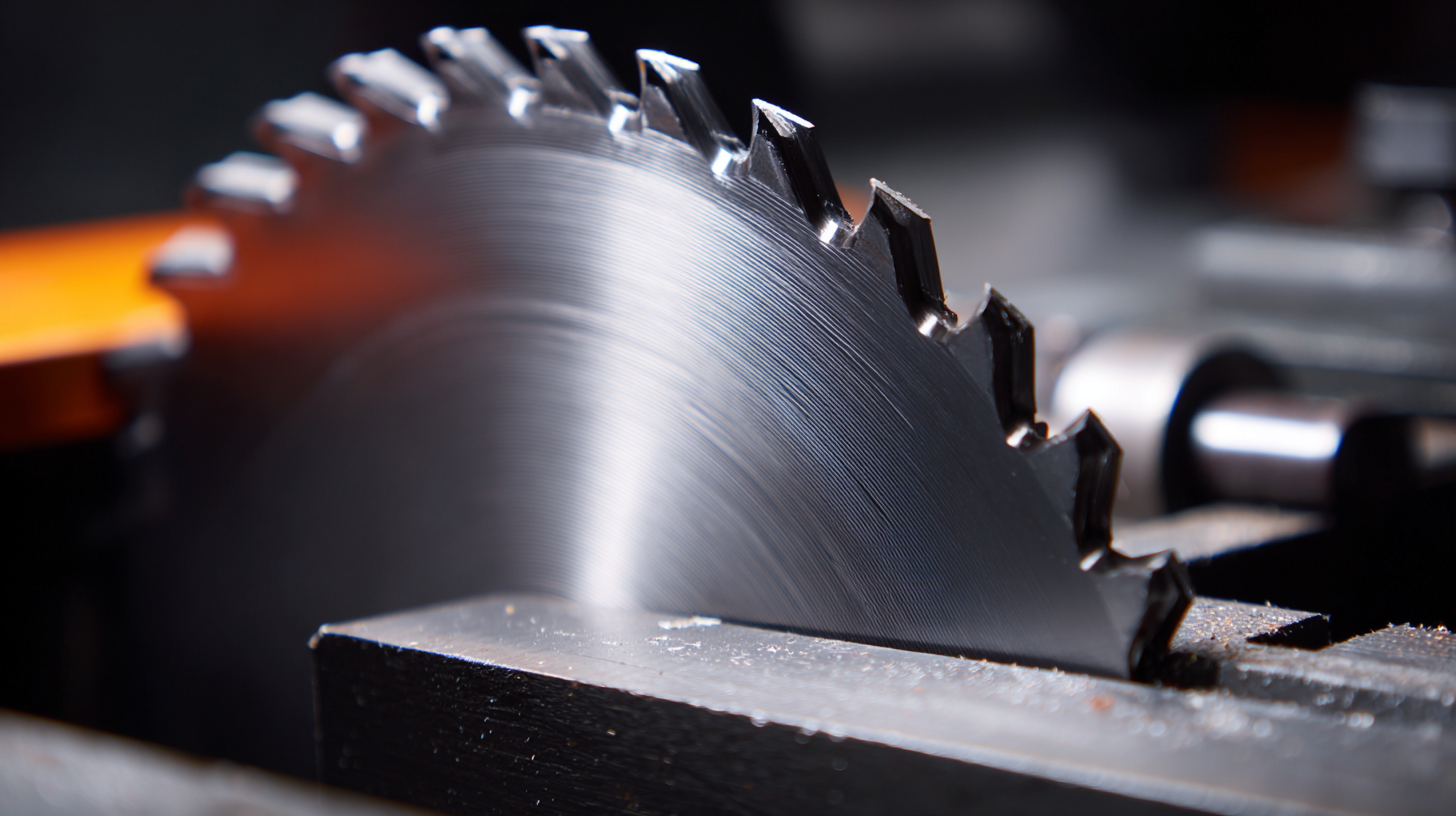

At the upcoming 2025 China Import and Export Fair, a spotlight will be cast on the latest innovations in Circular Saw Blade technology, marking a significant advancement in the woodworking and construction industries. This biennial event, known for its extensive display of cutting-edge products and technologies, will feature exhibitors showcasing a diverse range of Circular Saw Blades designed to enhance precision, durability, and efficiency in various applications. As industry leaders converge to exchange insights and innovations, attendees will have the opportunity to explore how these advancements can transform their operations and improve productivity. From materials science breakthroughs to smart technologies integrated into blade design, the 138th Canton Fair promises to be a pivotal moment for professionals seeking the most effective tools for their projects. As we delve into the exciting developments in Circular Saw Blade innovations presented at this fair, we can anticipate a future where tools are not only more efficient but also more sustainable, driving the evolving needs of the market.

The 2025 China Import and Export Fair is set to showcase the latest innovations in circular saw blade technology, highlighting emerging trends that are reshaping the industry. As manufacturers continue to prioritize efficiency and performance, advanced materials and cutting-edge designs are becoming the norm. Key developments include the integration of carbide-tipped blades for superior durability and the adoption of laser-cutting technology, which promises enhanced precision and reduced friction during operation.

Tip: When selecting a circular saw blade, consider the specific material you will be cutting. Different blades are designed for wood, metal, or composite materials, and using the right blade can significantly improve cutting efficiency and quality.

Another noteworthy trend is the rise of eco-friendly manufacturing processes in blade production. Companies are increasingly adopting sustainable practices, from sourcing materials responsibly to implementing energy-efficient technologies in their manufacturing plants. This shift not only benefits the environment but also meets the growing consumer demand for sustainable products.

Tip: Always check for certifications indicating eco-friendliness or sustainability in the circular saw blades you purchase, as these can provide assurances regarding the product's impact on the environment.

At the 2025 China Import and Export Fair, innovations in circular saw blade technology are set to take center stage, especially in the area of materials and coatings that significantly enhance cutting performance. Recent industry reports highlight that the demand for high-performance saw blades is projected to grow by 5.6% annually through 2030, driven by advancements in manufacturing technologies and the need for precision cutting in various industries. Manufacturers are increasingly focusing on developing blades that can withstand extreme conditions while providing superior durability and efficiency.

One of the key areas of innovation is the use of advanced carbide materials combined with proprietary coatings. For instance, a study from the Machinery and Tooling Institute revealed that blades with titanium nitride (TiN) coatings can increase cutting life by up to 40% compared to standard blades. Moreover, new hybrid materials, such as cobalt-infused tungsten carbide, are being introduced, which not only enhance the hardness of the blades but also improve their heat resistance, allowing for high-speed cutting without compromising performance. These advancements are crucial for manufacturing sectors where efficiency and precision are paramount, such as aerospace and automotive industries.

The ongoing innovations in circular saw blade production are increasingly aligned with sustainability practices, reflecting a growing awareness of environmental responsibilities within the manufacturing sector. A report by the Global Industry Analysts projects that the global circular saw blade market will reach USD 2.5 billion by 2026, driven in part by advancements in eco-friendly materials and processes. Manufacturers are exploring the use of recycled steel and sustainably sourced tungsten carbide, significantly reducing the carbon footprint associated with blade production.

Moreover, contemporary design methodologies emphasize longevity and efficiency, effectively minimizing waste. Utilizing cutting-edge technologies such as computer-aided manufacturing and laser cutting not only enhances precision but also reduces surplus material during fabrication. According to a study by MarketsandMarkets, the sustainable manufacturing practices in the tools sector can lead to cost savings of up to 30% over time, showcasing the economic benefits of sustainability alongside environmental stewardship. As the 2025 China Import and Export Fair approaches, these trends will likely dominate discussions, highlighting a collective shift towards environmentally conscious production among industry leaders.

At the 2025 China Import and Export Fair, innovations in circular saw blades have taken center stage, particularly in the comparative analysis of traditional versus modern designs. Traditional circular saw blades, while effective, often fall short in delivering precision and durability. These conventional blades typically feature simpler tooth designs and materials, which can lead to a shorter lifespan and less efficient cutting performance.

In contrast, modern circular saw blades incorporate advanced materials like carbide and high-speed steel, enhancing their robustness and cutting efficiency. Innovations such as laser-cut tooth geometry and specialized coatings result in blades that not only perform better but also handle a wider range of materials. Professionals in the woodworking and metalworking sectors are benefiting from these advancements, as they lead to cleaner cuts and reduced friction during operation.

**Tips for Choosing the Right Circular Saw Blade:** Always consider the material you'll be cutting; different blades are designed for specific materials such as wood, metal, or composites. Additionally, assess the tooth count—more teeth provide smoother cuts but require slower feeding rates, while fewer teeth allow faster cutting but may result in rough edges. Lastly, look for blades with manufacturer warranties, which can be indicative of their quality and longevity.

The 2025 China Import and Export Fair presents an exceptional opportunity for industry leaders in the circular saw blade sector to forge valuable connections and explore potential collaborations. As the global saw blade market is projected to reach USD 3.2 billion by 2026, with a compound annual growth rate (CAGR) of 4.8%, the significance of networking during such events cannot be overstated. Industry professionals will have the chance to discuss innovations and advancements within the sector, paving the way for technological advancements that can enhance productivity and efficiency.

In addition to showcasing cutting-edge saw blade designs, the fair will facilitate forums and workshops where leaders can engage in discussions about market trends, consumer demands, and sustainable practices. Recent reports indicate that nearly 60% of manufacturers are increasing their investment in sustainable production methods due to rising market demand for environmentally friendly products. These discussions will be crucial for stakeholders who aim to align their business strategies with changing industry dynamics and consumer preferences. Together, these networking opportunities will foster collaborations that drive innovation and growth in the circular saw blade industry.