FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

In today's manufacturing landscape, the importance of "Drill Through Metal" cannot be overstated. Industry expert John Smith, a leading engineer at Metalworks Inc., once said, "Precision in drilling is the backbone of metal projects." His words highlight the critical role that accurate drilling plays in achieving quality results.

Many projects fail due to poor execution in drilling processes. When drilling through metal, precision ensures fittings and components align correctly. Misalignment often leads to costly mistakes. The need for high-quality tools and techniques is clear. Yet, not every team prioritizes these standards, risking project integrity.

Furthermore, the choice of materials can greatly impact drilling results. Using the wrong drill bit can cause damage and inefficiencies. It's essential to understand the metal type before beginning. Failing to consider this can lead to wasted resources. Emphasizing the need for careful planning and execution will enhance overall project outcomes.

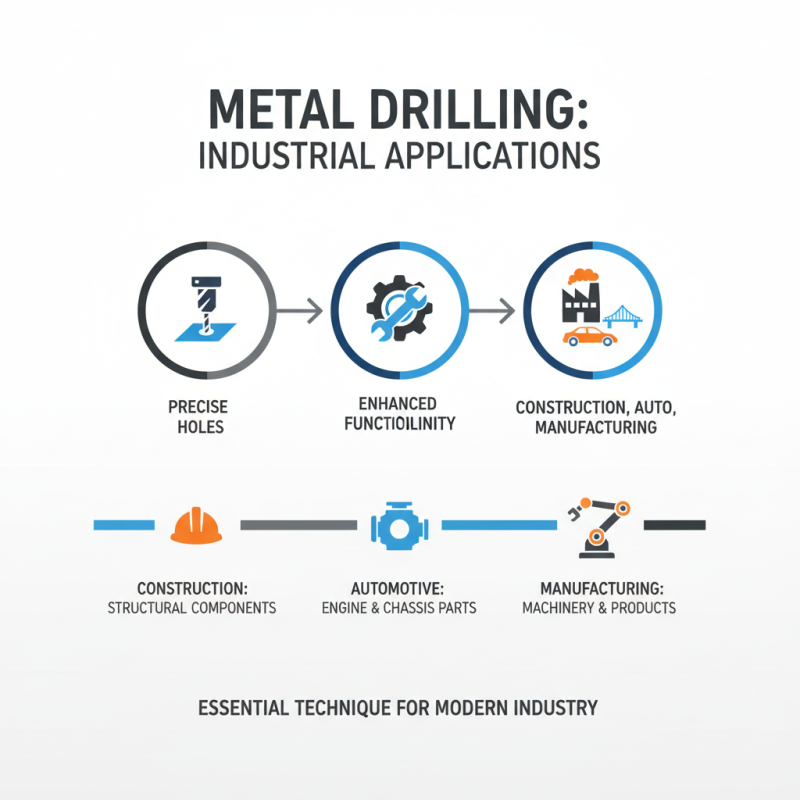

Drill through metal is an important technique utilized in various industrial applications. It involves creating precise holes in metal surfaces for multiple purposes. This method enhances the functionality of products. For instance, drilled metal components can be used in construction, automotive, and manufacturing industries.

Understanding drill through metal requires familiarity with different metals. Each type responds uniquely to drilling. Some are softer and easier to work with, while others are harder and may require special tools. A miscalculation can lead to poor results. It’s essential to choose the right drill bit, speed, and technique for each metal type.

Applications of drill through metal are widespread. In construction, it allows for the installation of fixtures and fittings. In automotive, it aids in assembly and repairs. However, mistakes often happen. A misaligned hole can compromise structural integrity. This oversight can affect safety and product durability. Recognizing the importance of precision in this process is crucial.

Drill through metal has become a crucial element in construction projects. This technique allows for precise and efficient work on various metal structures. Precision is key in construction, and drill through metal ensures that holes are correctly aligned. This is essential for fittings and fixtures to fit seamlessly.

Additionally, using drill through metal can enhance project timelines. Quick and accurate drilling reduces the time needed for assembly. A well-drilled hole can save hours of labor. However, it does require skilled operators. Improper techniques can lead to costly errors. Understanding the metal’s properties is vital. Not all metals respond the same way to drilling.

Furthermore, the durability of drill through metal strengthens construction integrity. Metal structures endure heavy loads, and proper drilling ensures reliability. There's a certain satisfaction in achieving flawless drilling. Yet, it’s worth reflecting on the challenges.

Managing heat buildup during drilling can be tricky. If neglected, it may weaken the metal. Construction professionals must consider these factors for success.

Drill through metal is crucial for various engineering projects. It ensures precision, reliability, and quality in applications ranging from construction to manufacturing. According to industry reports, projects that incorporate drill-through metal exhibit a 30% increase in structural integrity. This technique allows for efficient load distribution.

When working with drill-through metal, one must adopt certain best practices. Always select the right drill bit for your specific material thickness. A sharp, quality drill bit can reduce the risk of chipping and damage. Select lower speeds for thicker materials; this minimizes stress and prevents overheating. Remember, attention to detail is vital.

Tips: Use cutting fluid to enhance performance. It cools the bit and prolongs its life. Make sure to secure your metal piece firmly before drilling. Instability can lead to errors and injuries, which can be avoided with proper setup. Regularly inspect your tools for wear and tear. A slight chip on a bit may ruin your entire project. Respecting these nuances can yield better outcomes.

When using drill through metal, common mistakes can hinder your project. One major mistake is not selecting the right drill bit. A dull or incorrect bit can lead to poor results. It may cause uneven holes and damage the metal. Always check for compatibility before starting work.

Another common error is neglecting to prepare the metal properly. Failing to clean the surface can create problems. Dirt and grease can affect the drilling process. Take time to wipe down the area. This simple step can save you from larger issues later.

**Tips:** Always wear proper safety gear. Protect your eyes and hands during drilling. Excessive force can also be problematic. Rushing can lead to mistakes. Instead, take your time to ensure accuracy.

Lastly, many overlook cooling methods. Not using a lubricant can lead to overheating. This causes the bit to wear out quickly. Consider applying oil or another cutting fluid. It helps maintain temperature and prolongs the life of your tools.

| Mistake | Impact | Recommendation |

|---|---|---|

| Using Incorrect Drill Bit Size | Can lead to poor fit and structural weaknesses | Always verify the specifications before starting |

| Poor Lubrication | Increases friction, causing overheating and wear | Use appropriate cutting fluid for the material |

| Drilling Too Fast | Results in irregular holes and damage to tools | Follow recommended speed settings for the material |

| Neglecting Safety Precautions | Increases risk of injury and project accidents | Wear appropriate protective gear and follow safety practices |

| Insufficient Material Support | Can cause bending and misalignment | Ensure proper support for the metal being drilled |

The future of drill through metal techniques is evolving rapidly. Innovations in materials and methods are reshaping projects across various industries. One notable trend is the incorporation of advanced robotics. These robots can perform precise drilling tasks, enhancing speed and accuracy. They reduce human error and improve overall safety on job sites.

Another exciting development is the use of laser technology. Laser drilling offers cleaner cuts and is less damaging to the metal. This reduces waste and enhances the final product's quality. As these technologies become more accessible, projects could see significant efficiency improvements. However, one challenge remains: the cost of implementing such advanced tools.

Tips for using drill through metal techniques: Always test new methods on scrap materials first. This strategy prevents costly mistakes. Additionally, maintain equipment regularly to ensure optimal performance. A well-maintained tool is safer and more efficient. Embrace advancements, but reflect on their practicality for your specific needs. While new technologies are promising, they may not always align with your project requirements.