FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

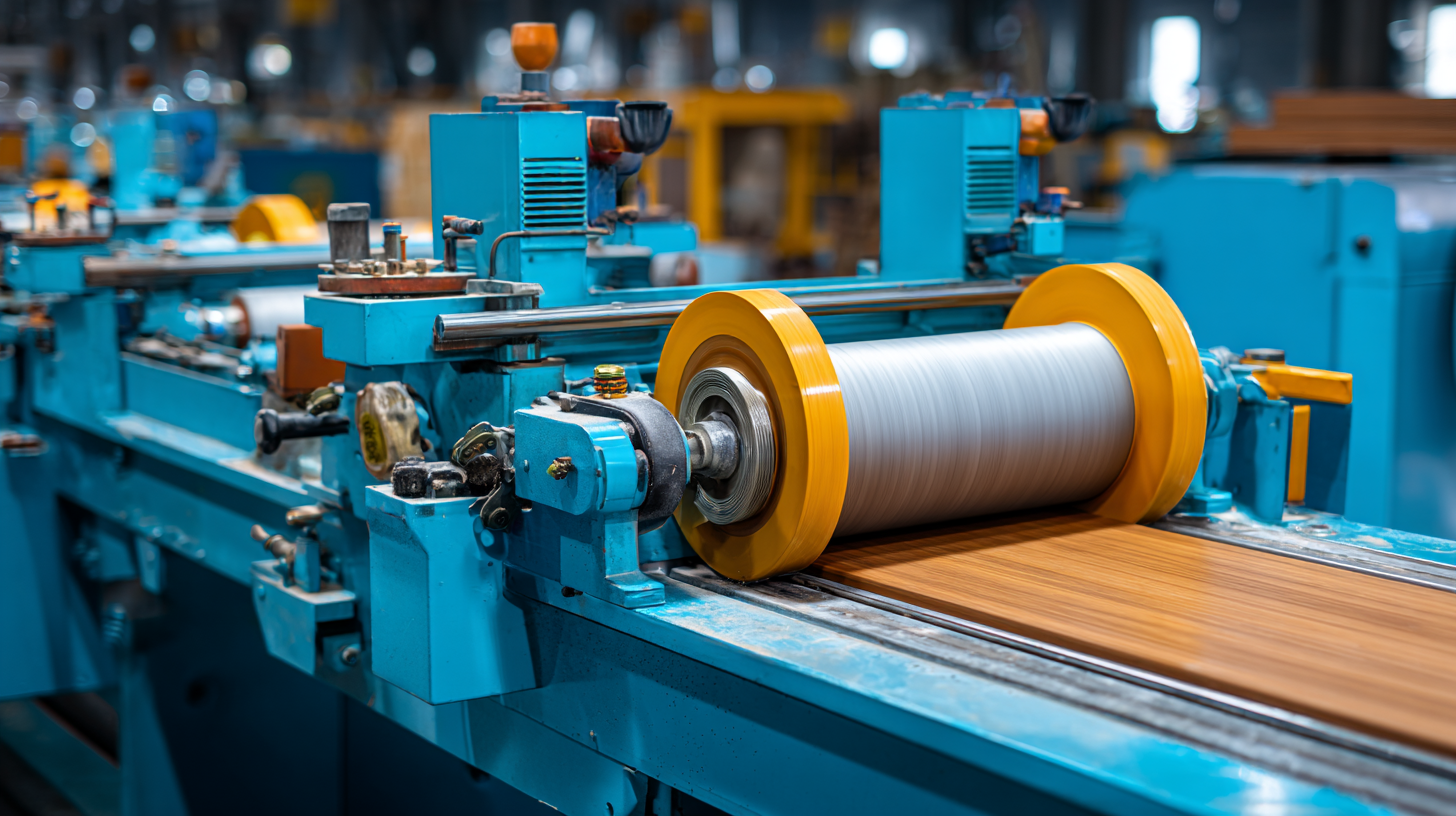

In the realm of woodworking, achieving a perfectly smooth surface is paramount, and this is where the Drum Sander comes into play. A tool often favored by both amateur and professional woodworkers, the Drum Sander enhances the quality of finishes by providing a consistent and even sanding experience. Renowned woodworking expert, Gary Katz, once stated, “A Drum Sander can turn an ordinary woodworking project into something extraordinary by ensuring every surface is flawless.” This statement encapsulates the essential role this equipment plays in woodworking.

Understanding the various types, features, and performance metrics of Drum Sanders is crucial for anyone looking to optimize their woodworking processes. With advancements in technology, modern Drum Sanders come equipped with a range of features designed to improve efficiency and accuracy, allowing woodworkers to select the best tool for their specific needs. In this article, we will delve into the intricacies of Drum Sanders, exploring their functionalities, the different types available, and practical tips to maximize their performance, ensuring that builders and crafters can achieve the superior finish they desire.

A drum sander is a powerful woodworking tool designed to achieve a smooth and flat surface on hardwood and softwood products. Unlike traditional sanders that may only offer a superficial finish, drum sanders utilize a rotating drum covered in sandpaper to remove significant amounts of material efficiently. According to the Woodworking Machinery Industry Association (WMIA), using a drum sander can increase productivity by up to 30% compared to manual sanding processes, allowing woodworkers to achieve higher quality finishes in less time.

The functionality of a drum sander lies in its construction and adjustable features. The drum itself typically ranges from 10 to 25 inches in width, making it suitable for a variety of workpiece sizes. Advanced drum sanders often come with features such as automatic feed systems and digital thickness gauges, ensuring consistent material removal and improved accuracy. A report from the American Association of Woodturners indicates that drum sanders can effectively reduce surface roughness by a staggering 50% compared to other sanding equipment, making them an invaluable asset in professional workshops and for serious hobbyists alike.

When it comes to drum sanders, understanding the various types available can significantly enhance your woodworking projects. Portable drum sanders are ideal for those who need flexibility; they can be easily moved around the workshop or taken to job sites. These models are designed to handle smaller tasks but may lack the power needed for heavier-duty jobs. On the other hand, stationary drum sanders provide stability and are typically more powerful, making them perfect for larger workpieces. These machines often come equipped with better dust collection systems, which is essential for maintaining a clean workspace.

Compact drum sanders strike a balance between portability and robustness. They are designed for those with limited space but still require quality performance. These models can tackle various sanding tasks efficiently while being easy to store when not in use. Depending on your specific needs—whether that be portability, stationary power, or compact design—understanding these different types will help you choose the best drum sander for optimal results in your woodworking endeavors.

When choosing a drum sander for woodworking, several key features warrant careful consideration, particularly motor power, belt size, and dust collection systems. The motor power of a drum sander significantly influences its performance. According to a report by Woodworker’s Journal, a motor with at least 1.5 to 3 horsepower is recommended for serious woodworking projects, as it provides the necessary strength to handle various wood types efficiently.

Tip: Always consider investing in a dust collection system. Research indicates that effective dust collection can reduce airborne particles by approximately 98%, greatly enhancing the work environment and protecting your health. A good system not only minimizes cleanup time but also prolongs the lifespan of the sander by preventing dust accumulation in the motor and internal components.

Belt size also plays a crucial role in the effectiveness of sanding. Standard belt sizes typically range from 3 to 4 inches, allowing users to cover larger surfaces more quickly. However, larger belt sizes can lead to increased weight, which may affect maneuverability. It’s essential to balance size with usability to achieve optimal results.

When considering the performance metrics of drum sanders, three primary aspects come into play: speed, sanding thickness, and surface finish quality. Speed is critical in any woodworking project, as it dictates how quickly a job can be completed. Advanced drum sanders offer varying speeds that can be adjusted based on the material being worked on, resulting in efficiency while maintaining the desired finish.

Sanding thickness is another crucial performance metric. It determines the amount of material removed with each pass, affecting both the final dimension of the wood piece and the time required to achieve it. Adjustability in sanding thickness allows woodworkers to tackle a range of projects, from light sanding to more aggressive material removal. Additionally, the quality of the surface finish is paramount; a finer finish translates to less time spent on finishing processes later. Recent studies in wood machining have focused on optimizing these parameters, exemplified by using techniques like artificial neural networks to refine sanding conditions.

This optimization not only enhances the quality of the final product but also promotes efficiency in achieving a smooth surface across various wood types.

When selecting the right drum sander for your woodworking projects, it’s essential to consider both the type of sander and its features. Drum sanders are designed for rapid sanding on larger surfaces, making them ideal for flattening boards or preparing wood for finishing. There are various types available, including portable models for smaller jobs and industrial-sized sanders for more extensive operations. Understanding the performance metrics, such as drum size and motor power, will help you make an informed decision tailored to your specific project requirements.

**Tips for Choosing a Drum Sander:**

1. Evaluate the size of your projects and shop space. If you have limited room, a more compact drum sander may be a better fit.

2. Look for features like adjustable speed settings and dust collection systems to enhance your sanding experience.

3. Read reviews and comparisons from trusted sources to find models that have performed well in similar tasks, ensuring you select a machine that meets your quality expectations.