FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

When embarking on metalworking projects, the importance of selecting the right tools cannot be overstated. One essential tool that plays a crucial role in achieving precision and efficiency in drilling metal materials is the Hole Saw Drill Bit for Metal. Understanding the unique features and capabilities of these drill bits can significantly impact the quality of your work while also saving you time and effort.

In this guide, we will explore the key considerations when choosing a Hole Saw Drill Bit for Metal. Factors such as material compatibility, tooth design, and size will be discussed to help you make informed decisions tailored to your specific project needs. With several options available in the market, knowing what to look for can enhance your drilling experience and ensure optimal results in your metal work.

Whether you are a seasoned professional or a DIY enthusiast, mastering the art of selecting the right Hole Saw Drill Bit for Metal will empower you to tackle a wide range of applications with confidence. Join us as we delve deeper into the essential aspects that will guide you in making the best choice for your metal projects.

When selecting the right hole saw drill bit for metal projects, it’s essential to understand the fundamentals of these tools. Hole saws are specifically designed to create clean, circular holes in various materials, including metal. They consist of a cylindrical saw blade, often with serrated edges, mounted on a mandrel. This design allows for efficient cutting through thicker metals, making them invaluable for both professional and DIY tasks.

Different types of materials and gauges require specific hole saw drill bits, often made from materials like high-speed steel or bi-metal construction for enhanced durability. The tooth configuration and pitch play a crucial role in determining the effectiveness of the cut, as finer teeth yield smoother edges while coarser teeth allow for quicker cutting but may result in rougher finishes.

Understanding the specifications such as diameter, depth of cut, and compatibility with your drill can greatly aid in choosing the right bit. Properly matching the hole saw to the thickness and hardness of the metal will optimize performance, reduce wear on the tool, and achieve the desired precision. By familiarizing yourself with these aspects, you'll be better equipped to select the most suitable hole saw drill bit for your metalworking projects.

This chart illustrates the effectiveness of various hole saw drill bit types for metal projects based on a comprehensive evaluation of their cutting speed and durability.

When selecting the best hole saw drill bit for metal projects, several key features must be taken into account to ensure optimal performance and durability. First and foremost, the material composition of the hole saw is critical. High-speed steel (HSS) and bi-metal designs are favored for their robustness, allowing for the effective cutting of various metal types, including mild steel and aluminum. According to industry reports, bi-metal hole saws can achieve a cutting life up to three times longer than standard carbon steel holes, making them a more cost-effective option for frequent use.

Another vital consideration is the tooth design and pitch of the hole saw. A raker tooth design is known for delivering smooth cuts in metal, and a tooth pitch that is too coarse may lead to tearing rather than cutting, impacting the finish of the workpiece. Research indicates that a pitch of 4-6 teeth per inch is optimal for metal applications, providing a balance between cut speed and finish quality. Additionally, the diameter of the hole saw is crucial depending on the intended project. A well-chosen size will minimize the need for additional operations, thus enhancing overall efficiency. Taking these aspects into account will ensure that the chosen hole saw drill bit is well-suited for metal projects, ultimately leading to superior results.

| Feature | Description | Importance Level |

|---|---|---|

| Material Composition | Determine if the hole saw is made from high-speed steel (HSS) or bi-metal for durability and performance. | High |

| Tooth Design | Look for a tooth pitch that allows for efficient cutting and prevents binding. | Medium |

| Cutting Depth | Ensure that the hole saw can handle the thickness of the metal you are working with. | High |

| Size Options | Select from a range of sizes to suit different projects and hole diameters. | Medium |

| Compatibility | Check if it is compatible with your drill and any extension arbors you may need. | High |

| Price | Evaluate the cost in relation to the quality and durability of the product. | Medium |

When choosing the best hole saw drill bit for metal projects, understanding the right materials and coatings is essential for achieving optimal results. The material of the hole saw itself greatly influences its cutting efficiency and longevity. For metal work, high-speed steel (HSS) is a preferred choice, thanks to its durability and ability to withstand high temperatures generated during cutting. Cobalt-infused HSS further enhances cutting performance and is particularly effective for harder metals. Selecting the appropriate core material can help ensure that the hole saw maintains its sharpness and effectiveness over extended periods of use.

Additionally, coatings play a vital role in enhancing the performance of hole saws. Titanium and carbide coatings provide significant advantages, such as reducing friction and improving heat resistance, which leads to smoother cuts and longer life spans for the bits. A coated hole saw can better resist wear and tear, making it a wise investment for frequent metalworking tasks.

When assessing options, consider factors such as the type of metal being drilled and the specific project requirements to determine the ideal combination of material and coating that will offer the best results in your metal projects.

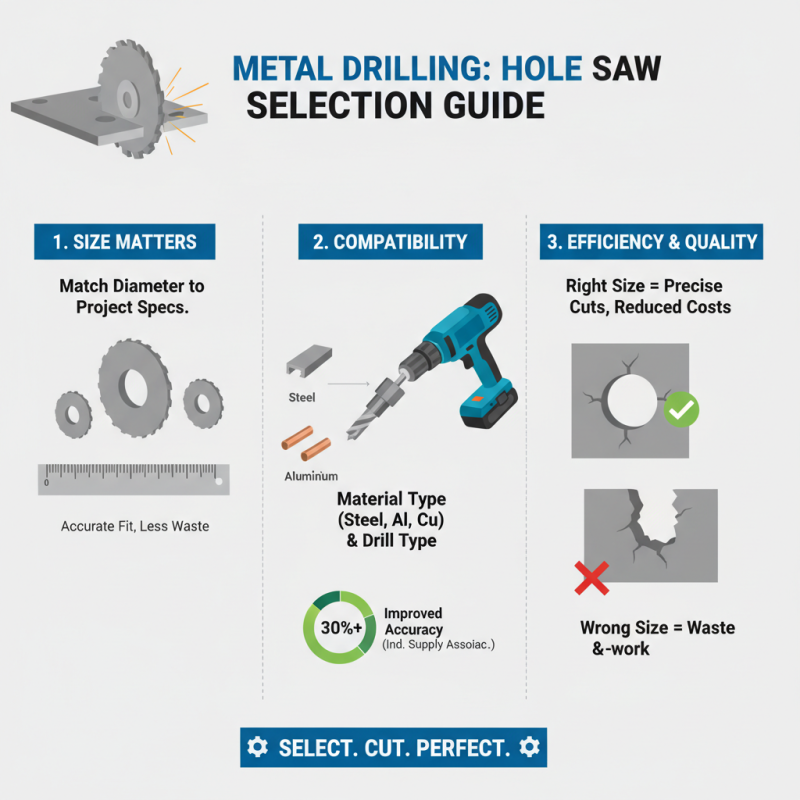

When selecting a hole saw drill bit for metal projects, size and compatibility are crucial factors that can significantly impact the efficiency and quality of the work. According to data from the Industrial Supply Association, the right size hole saw can improve drilling accuracy by as much as 30%, ensuring a precise fit for any application. It is essential to match the hole saw’s diameter with the specifications required for the project, as using incorrect sizes can lead to material waste and increased labor costs.

Compatibility also extends to the drill itself. The U.S. Bureau of Labor Statistics reports that improper tool compatibility is a common cause of job delays in metalworking projects. For optimal performance, confirm that the hole saw is compatible with the drill's chuck size and type. Most drill bit sizes range from 1/2 inch to 6 inches, making it vital to assess the requirements of your specific metal project beforehand. Consulting technical datasheets and using standard sizing guides will help you select the best hole saw drill bit that not only fits well but also enhances the overall precision and efficiency of your work.

When working on metal projects, using the right tools is crucial for achieving precise results. Hole saw drill bits are specifically designed for cutting through various metals cleanly and efficiently. However, to ensure both effectiveness and safety, proper techniques and precautions must be followed.

One important tip is to always use the correct speed settings on your drill. Metal typically requires a slower speed compared to wood, which helps to prevent the bit from overheating and extends its lifespan. Additionally, applying cutting lubricant can further decrease friction and ensure a smoother cut.

Safety should also be a top priority when using hole saw drill bits. Always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect against metal shavings and potential injuries. Ensure that the workpiece is securely clamped or held in place to prevent it from shifting during the drilling process. Finally, be mindful of the distance between your hands and the drill bit to avoid accidents. By following these tips, you can safely and effectively use hole saw drill bits for your metal projects.