FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

When it comes to tackling the challenge of how to effectively drill through metal, it pays to heed the advice of experts in the field. Among them is John Mathews, a seasoned metalworking specialist, who once stated, “The key to efficiently drilling through metal lies in selecting the right tools and techniques for the job.” This principle underscores the importance of preparation and knowledge when approaching metal drilling tasks, whether for a DIY project at home or for professional applications.

Understanding the intricacies of drilling through metal can significantly enhance both the quality of workmanship and the efficiency of the process. With an array of metals presenting different challenges, from soft aluminum to hardened steel, the appropriate techniques and tools can make a world of difference. By cultivating knowledge about drill bits, speeds, and feed rates, one can not only improve drilling performance but also extend the life of both the drill and the workpiece. In this guide, we will explore top tips and practical advice that will empower you to drill through metal like a pro, ensuring your projects are executed with precision and confidence.

When it comes to drilling through metal, having the right tools is crucial for achieving professional results. According to a report by Grand View Research, the global power tools market is expected to reach $41.88 billion by 2025, indicative of the increasing demand for high-quality drilling solutions. Essential tools for drilling metal include high-speed steel (HSS) drill bits, cobalt drill bits, and specialized metal hole saws. HSS bits are versatile and can handle various metals, while cobalt bits are specifically designed for tougher materials, making them ideal for stainless steel and other hard alloys.

In addition to drill bits, a reliable drill press can significantly enhance precision and control when drilling through thicker metal sheets. A survey conducted by the Technical Institute for Work and Technology revealed that using a drill press improves accuracy by up to 30% compared to handheld drills. Accessories such as cutting fluids and deburring tools are also vital for maintaining tool longevity and ensuring clean holes. With the right combination of tools, you can ensure effective metal drilling, reduce wear and tear, and achieve smoother finishes, elevating your craftsmanship to a professional level.

| Tool | Description | Recommended Material | Best Practices |

|---|---|---|---|

| Drill Press | A stationary tool offering precision and stability for drilling | Steel, Aluminum | Secure workpiece, use proper speed and pressure |

| Cobalt Drill Bits | High-speed steel bits with additional cobalt for hardness | Stainless Steel, Hard Metals | Use cutting oil for lubrication |

| Step Drill Bits | Used for drilling holes of various sizes in thin metal | Sheet Metal | Start with a pilot hole for precision |

| Countersink Bits | Create a conical hole for flush screw heads | Various Metals | Follow with the appropriate screw size |

| Lubricants | Fluids to reduce friction and heat during drilling | Not applicable | Apply liberally for best results |

Choosing the right drill bit is crucial when drilling through different types of metal. According to a recent report from the Metalworking Industry Association, improper drill bit selection can lead to decreased efficiency and increased tool wear, often resulting in a 30% reduction in productivity. For softer metals such as aluminum, high-speed steel (HSS) bits are usually adequate due to their ability to maintain sharpness and resist heat. However, for harder materials like stainless steel or titanium, cobalt-infused drill bits are recommended for their superior strength and durability.

When drilling through metals, it’s also essential to consider the design of the drill bit. Bits with a split-point tip can significantly improve precision and reduce walk-off, which is particularly beneficial when starting holes on flat surfaces. It is also recommended to apply cutting fluid during the drilling process to prolong the life of the bit and improve the finish of the hole. Following these tips can lead to a smoother experience, ensuring you drill like a pro and achieve professional results in your metalworking projects.

Preparing your workspace is crucial for safe and efficient drilling through metal. According to a report by the National Institute for Occupational Safety and Health (NIOSH), nearly 20% of workplace accidents in construction involve power tools, highlighting the importance of a well-organized environment. Start by ensuring that your drilling area is clean and free from any debris that could pose a tripping hazard. Keep your tools organized in a toolbox and ensure that you have adequate lighting to clearly see your marking and drilling spots.

Another critical aspect is to have the right safety gear readily available. The Occupational Safety and Health Administration (OSHA) recommends wearing safety glasses, gloves, and steel-toed boots when operating power tools. Additionally, using a sturdy workbench with clamps to secure your metal piece can improve both safety and accuracy. A survey conducted by the Machinery Safety Association found that well-prepared workspaces can reduce the risk of accidents by up to 40%, underscoring the importance of taking the time to set up your workspace appropriately before starting any drilling project.

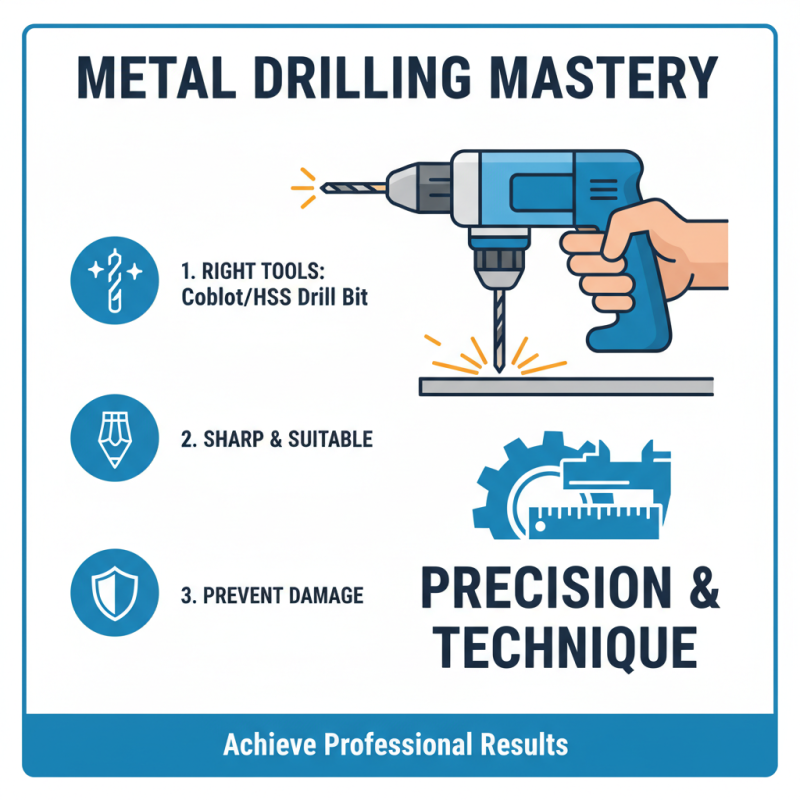

When it comes to drilling through metal, precision and technique are vital for achieving professional results. First, always start with the right tools. A high-quality drill bit, preferably made from cobalt or high-speed steel, is essential for penetrating tough materials. To prevent any damage to both the drill and the workpiece, ensure that the drill bit is sharp and appropriate for the type of metal you are working with.

Before drilling, it’s important to prepare your metal workpiece properly. Secure it firmly using a clamp or vice to prevent any movement during the process. Mark the drilling spot clearly to maintain accuracy as you drill. Additionally, applying a lubricant, like cutting oil, can help reduce friction and extend the life of your drill bit while ensuring a cleaner cut. Once you start drilling, use a steady, moderate speed and apply gentle pressure—too much force can lead to mistakes or even breakage of the drill bit. By following these steps, you can drill through metal like a pro with minimal hassle and maximum efficiency.

When drilling through metal, common mistakes can lead to frustration and damage to both the material and the drill bit. One prevalent error is using the wrong type of drill bit. High-speed steel (HSS) bits are generally recommended for metal, while carbide-tipped bits can offer superior performance on tougher materials. Ensuring you’re equipped with the right tools is crucial in achieving clean and effective results.

Another frequent oversight is neglecting to use cutting fluid or lubricant. Many drillers forget that metal can heat up quickly, causing bits to dull and metal to work-harden, making it harder to drill through. Applying a suitable cutting fluid not only reduces friction but also extends the lifespan of your drill bit. Keeping the drill bit cool and adequately lubricated will help in maintaining its sharpness and efficiency.

Lastly, it's essential to avoid applying excessive pressure while drilling. While it may seem intuitive that pushing harder would yield faster results, it often leads to stripped screws and broken drill bits. Instead, let the drill do the work, maintaining a steady pace, and allowing the bit to penetrate the metal naturally. By steering clear of these common pitfalls, you’ll ensure a successful drilling experience.

This chart illustrates the top tips for drilling metal, rating each tip on a scale of 1 to 10 based on its importance. Proper drill bit selection is crucial, followed by using the correct speed and adequate lubrication to ensure a successful drilling process.