FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

When tackling DIY projects, selecting the right tools can make a real difference. An essential tool in masonry work is the Brickwork Drill Bit. According to industry reports, the demand for quality drill bits has risen by 20% over the past five years. This growth reflects the DIY community's increasing focus on efficiency and precision.

Expert Bob Mason, a leading figure in the drill bit industry, once said, "A good Brickwork Drill Bit can turn a challenging project into a smooth experience." This statement underscores the importance of choosing high-quality tools. The market offers various options, each designed for specific tasks. However, not every Brickwork Drill Bit can deliver the desired results.

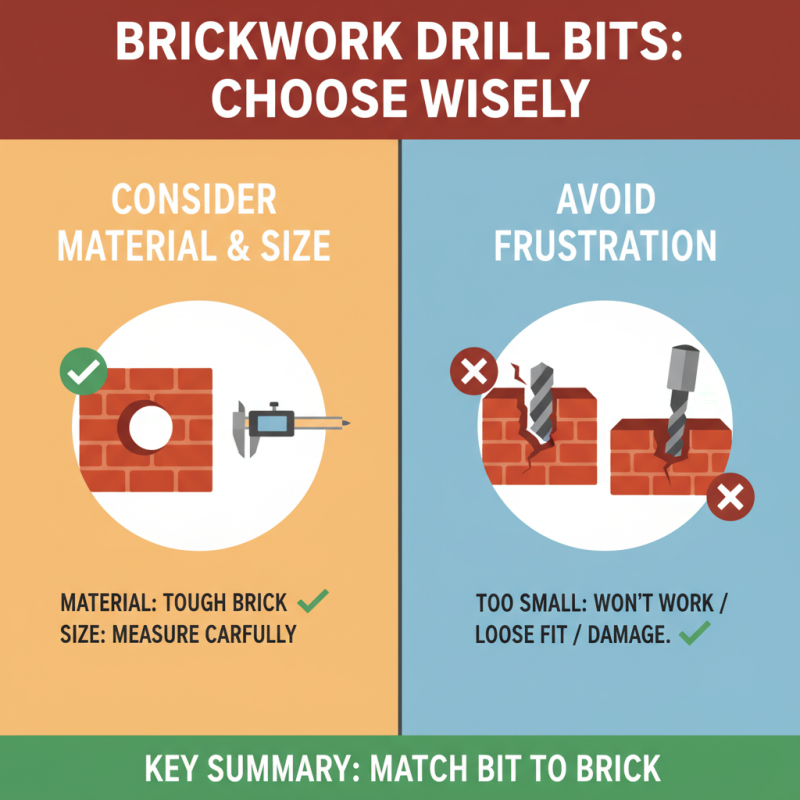

If the wrong bit is chosen, it can lead to frustrating setbacks. For example, using a masonry bit instead of a proper brickwork variant may chip the material. The process can also waste time and resources. Thus, understanding the features of the top drill bits is crucial. Choosing wisely can significantly enhance the outcome of your DIY project.

When selecting brickwork drill bits, it's crucial to understand their key features. The material of the bit is significant. High-speed steel (HSS) is common, but carbide-tipped options offer more durability. These bits can handle tougher materials, making them suitable for various DIY projects.

Size matters too. Bits come in various diameters and lengths. A smaller diameter bit is ideal for precise holes. A larger one may be necessary for anchors or larger screws. It's essential to choose the right size to avoid damaging the brick or weakening its structure.

Another aspect to consider is the design of the drill bit. Some have a pointed tip, providing more accurate entry. Others feature a flat or chisel tip, allowing for faster drilling in tougher materials. However, opting for the wrong design can lead to broken bits or ineffective drilling. It's vital to reflect on these choices, as they can significantly impact your project's outcome.

When diving into any DIY project involving brickwork, having the right tools is crucial. Many enthusiasts often overlook the importance of selecting suitable drill bits. Traditional bits might not have the necessary durability or precision. A report from the American Society for Testing and Materials highlights that specialized brickwork drill bits can increase efficiency by up to 30%. This statistic reflects how the right choice can save time and effort.

Typically made from materials like carbide or diamond, these bits cut through brick, mortar, and concrete effectively. However, not all drill bits perform equally over time. Some can wear down quickly, leading to frustrating experiences. A study by the National Institute of Standards and Technology found that 25% of DIYers faced issues due to improper bit selection. Such challenges can delay projects and increase costs unexpectedly, pushing the importance of research and testing.

Moreover, correct drill speed and pressure are essential. Many enthusiasts apply too much force, decreasing both effectiveness and tool lifespan. A DIYer should consider a bit's design carefully, as the right angle and tip type matter significantly. The nuances in these details can lead to smoother drilling experiences and better results overall. While it might seem trivial, selecting the right brickwork drill bit is a decision that should not be taken lightly.

When tackling a DIY project that involves brickwork, choosing the right drill bit is essential. The performance of each drill bit can vary significantly. Some bits may excel in certain conditions, while others may fall short. For example, a wider bit could make a larger hole faster, but precision might be sacrificed. This could lead to mismatched fittings or an unstable structure, which many DIYers overlook.

In addition, the material and design of the bits play a crucial role. Diamond-tipped bits are often preferred for their durability, but they can be expensive. On the other hand, standard masonry bits are more affordable but may dull quickly. Users frequently find themselves questioning their options. Does spending more on a durable bit really pay off? Or would a less expensive option suffice for smaller tasks? Experimenting with various types might provide insight into personal preferences.

Every project offers a learning experience. Not all drill bits are created equal, and finding the right one requires some trial and error. You may think you have the perfect bit, only to discover it isn't effective against harder materials. It's important to reflect on each outcome and understand what works best in different situations.

When choosing the right drill bit for brickwork, consider the material and size. Brick is tough and often unforgiving. A poorly chosen bit can lead to frustration. Measure your hole size carefully. A drill bit that is too small won’t work. Conversely, one that is too large may damage the brick.

Pay attention to the design of the drill bit. Look for carbide-tipped options that can handle harder surfaces. Spiral flutes help remove debris, which is vital for efficiency. If you're drilling masonry regularly, investing in quality bits will save time. Remember, practice makes perfect. Don’t be discouraged by failure; adjust your approach and try again.

Check your drill settings before you begin. High speeds are not always necessary. Find a balance between speed and pressure. Overdrilling can crack the brick. Test on a scrap piece if possible. Every project can reveal new lessons. Embrace those learning moments for better future results.

When using brickwork drill bits, safety should be a top priority. Always wear protective eyewear to shield your eyes from flying debris. A dust mask can help prevent inhaling particles when drilling into brick. Heavy-duty gloves are also recommended to protect your hands from sharp edges or slips. It's easy to overlook these basic precautions, but they can prevent injuries.

Proper handling of the drill is crucial. Keep a firm grip and maintain a steady hand while drilling. If the bit gets stuck, avoid forcing it. Instead, remove it gently to prevent damage. Ensure the area is clear of obstacles and that you have adequate lighting. Reflect on your workspace; clutter can lead to accidents. While brick may seem sturdy, drill slowly to avoid overheating the bit. Remember, patience plays a role in achieving a clean hole.

| Bit Type | Diameter | Length | Material | Usage |

|---|---|---|---|---|

| Masonry Bit | 6 mm | 100 mm | Carbide | Brick, Concrete |

| Diamond Core Bit | 10 mm | 150 mm | Diamond | Holes in Tiles |

| Spade Bit | 13 mm | 200 mm | Steel | Wood and Masonry |

| Hammer Drill Bit | 8 mm | 120 mm | Titanium | Concrete and Brick |

| Glass and Tile Bit | 5 mm | 100 mm | Carbide | Ceramic Tiles |

| SDS Plus Bit | 12 mm | 200 mm | Steel | Heavy Duty Drilling |

| Countersink Bit | 10 mm | 50 mm | High-Speed Steel | For Smooth Finishing |

| Twist Drill Bit | 9 mm | 110 mm | Cobalt | General Purpose |

| Paddle Bit | 16 mm | 150 mm | Steel | For Large Holes |