FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Using a hole saw drill bit for metal can be challenging. These tools are essential for creating precise holes in various metal materials. However, many users encounter problems during the drilling process. Misalignment, overheating, and dull blades are common issues.

Understanding your project is vital. Choose the right hole saw drill bit for metal based on thickness and type. Not all bits are created equal; some are better for certain metals. Furthermore, proper setup and technique can greatly enhance your drilling experience. A steady hand and consistent pressure are crucial for accuracy.

In this guide, we will explore ten actionable tips to improve your hole saw drill bit for metal usage. These tips aim to help avoid mistakes and make your work more efficient. With the right approach, you can achieve cleaner cuts and longer-lasting tools. Stay tuned for insights that could transform your drilling tasks.

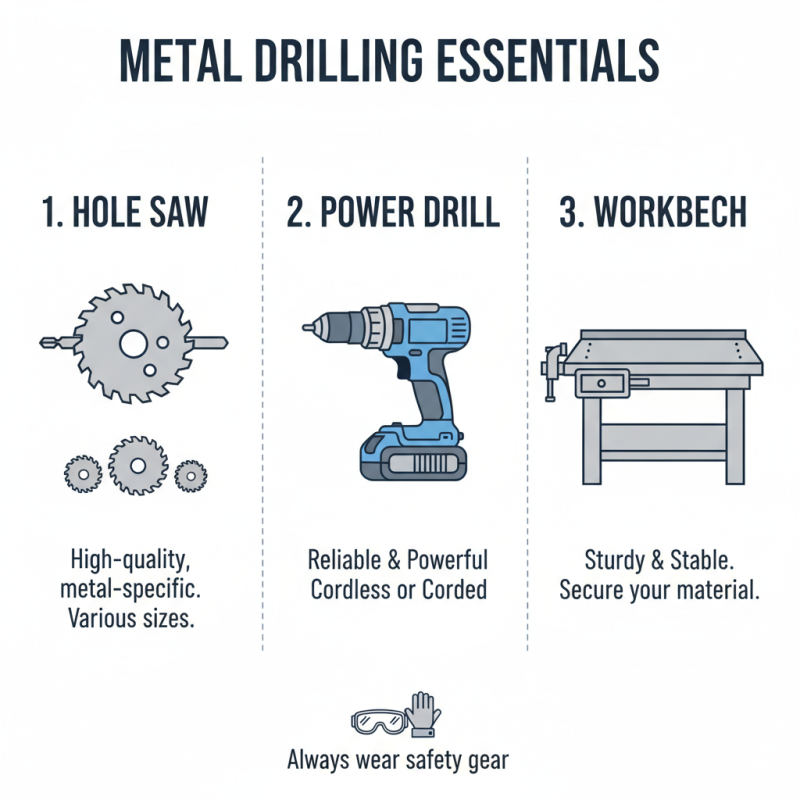

When drilling holes in metal, having the right tools is essential. Choose a high-quality hole saw made for metal. These saws come in various sizes for different applications. Additionally, ensure you have a reliable drill and a sturdy workbench to maintain stability.

Before starting, gather these essential materials: cutting oil, clamps, and safety gear. Cutting oil keeps the drill cool and extends the life of the bit. Clamps secure the metal piece in place, preventing movement during drilling. Safety gear, like goggles and gloves, protects you from flying debris and sharp edges.

Tip: Always make pilot holes before using the hole saw. This reduces stress on the bit and improves accuracy. Ensure your drill's RPM is suitable for the material. Too high can overheat the bit; too low may stall the drill. Experiment with different speeds on scrap metal to find the sweet spot. Keep an eye on the bit; if it’s dull, replace it promptly. Dull bits can cause frustration and lead to poor results.

Selecting the right hole saw bit for your specific metal type is crucial for achieving clean cuts. Different metals require specific materials for drill bits. For example, high-speed steel (HSS) is effective for softer metals like aluminum. However, these bits may dull quickly on tougher materials.

Carbide-tipped hole saws are ideal for stainless steel and other hard metals. They maintain sharpness longer and resist heat. According to a recent industry report, using the right bit can improve efficiency by up to 30%. This can save valuable time in projects.

It’s essential to consider the thickness of the metal as well. A thin metal may bend or warp if the wrong bit is used. Users should also remember to select the proper speed settings on their drills. Too high of a speed can damage both the bit and the material. Always check your specifications and adapt as needed.

Choosing the right drill speed is crucial for effective metal cutting. A slower speed is often better for thicker materials. For thin metals, a higher speed may work well. It depends on the material type. Remember, every metal behaves differently under the drill bit.

Testing is key. You might start at a moderate speed and adjust as you see fit. Too fast may result in burning the metal. On the other hand, too slow could lead to excessive wear on the bit. Finding a balance takes practice. Your technique may change depending on the specific job.

Keep an eye on the bit’s temperature. If it’s too hot, you likely need to slow down. Use cutting fluid to maintain a cooler temperature. This can prolong the life of the hole saw. Don't forget to let the tool rest if you sense it’s overheating. Adjusting the speed isn't always straightforward. Sometimes, trial and error can lead to better results. Expect a learning curve with each new type of metal.

Achieving accurate hole placement with hole saw drill bits can greatly impact your project. A study found that improper placement can lead to material waste, costing up to 15% of project budgets. To avoid this, always mark your drilling spot clearly. Use a center punch to create a small dimple. This helps keep your drill bit steady during the initial cut, reducing the risk of slippage.

Tip: When selecting a hole saw, ensure it's designed specifically for metal. The right teeth configuration can greatly enhance your drilling precision. For instance, bi-metal holes saws are known for their durability and effectiveness. They often provide cleaner cuts, which is vital for tight tolerances.

Don’t forget to check your drill speed. Metal requires slower speeds to prevent overheating. Aim for 300-500 RPM for optimal results. If drilling becomes too heat-sensitive, consider using cutting fluid to lubricate the bit and prolong its life. This practice not only preserves the bit but also improves cutting accuracy.

Reflect on the surface you're drilling into. Uneven surfaces can affect alignment. It may be beneficial to practice on scrap metal first. Acquiring skills through practice can reveal noticeable improvements in your accuracy. Each of these techniques enhances not just precision, but also the overall quality of your work.

Drilling metal with hole saws can be tricky. It's essential to prioritize safety. According to the Bureau of Labor Statistics, injuries in construction often result from improper tool use. Always wear eye protection, as metal shavings can cause serious eye damage. Steel-toed boots protect your feet from falling objects. Gloves are useful but can be a hazard if they get caught in the drill.

Check the drill bit for damage before use. A worn or damaged hole saw can break and lead to accidents. Keep your work area tidy. Clutter can lead to slips and trips. Make sure you use the right drill speed for the metal type. Slower speeds are often more effective for thick materials. Ensure your workpiece is securely clamped down to avoid movement during drilling. Movement can cause imprecise holes and increase the risk of injury.

Stay focused while drilling. Distractions can lead to mistakes. If you sense that something is off, stop immediately. Take breaks as needed to prevent fatigue. Overworking can diminish your attention to safety protocol. Also, always have a first aid kit nearby, just in case. While it’s ideal to work safely, accidents can still happen quietly. Reflecting on your process is the key to improvement.