FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

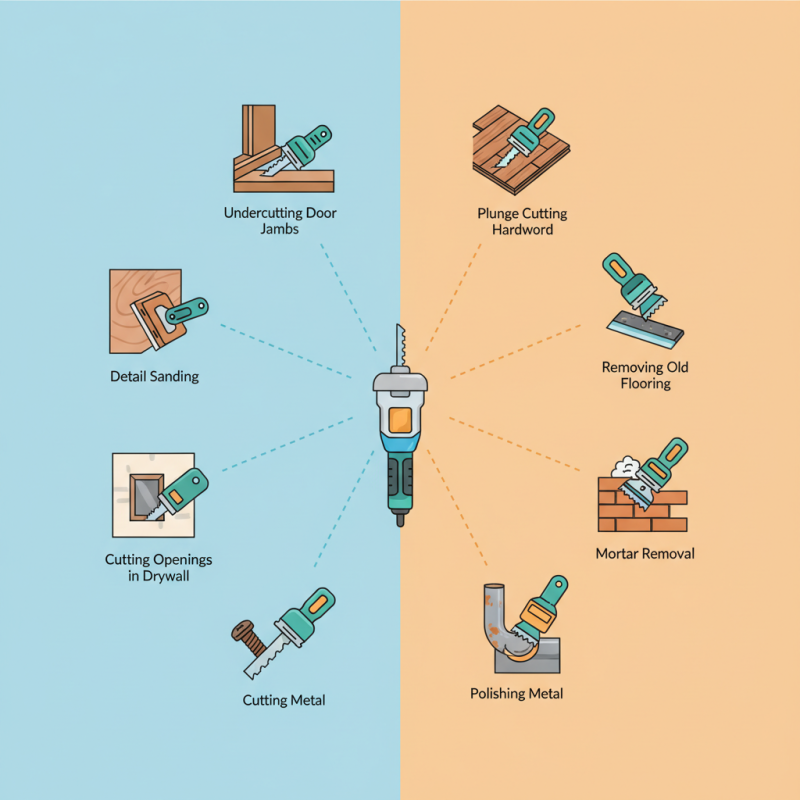

When it comes to versatile tools that can revolutionize your DIY projects, the oscillating tool stands out as an unsung hero in the toolbox. Its unique design allows for a wide range of applications, making it an indispensable companion for both seasoned professionals and enthusiastic hobbyists. While many are familiar with its basic functions, such as sanding and cutting, the true potential of the oscillating tool often remains underestimated.

In this exploration of the top 10 uses for oscillating tools that you may not have known about, we will dive into innovative applications that can enhance your efficiency and creativity. From intricate detailing to heavy-duty renovations, the oscillating tool can tackle tasks that span beyond traditional expectations. Whether you're looking to streamline your workflow or discover new techniques, understanding these lesser-known uses will empower you to maximize the capabilities of this remarkable tool. Get ready to unlock the full potential of your oscillating tool and elevate your project outcomes!

Oscillating tools have revolutionized the way we approach home improvement tasks, offering innovative solutions that enhance efficiency and precision. One of the lesser-known applications of these versatile tools is in intricate woodwork. The ability of an oscillating tool to make precise cuts in tight corners and along delicate edges makes it ideal for detailed trim work, allowing homeowners to achieve a professional finish without requiring extensive carpentry skills.

Another inventive use of oscillating tools is in the realm of flooring. When renovating or repairing floors, removing old tiles or vinyl can be a cumbersome task. An oscillating tool fitted with a specialized attachment can easily detach glue and scrape away materials, significantly speeding up the process. This capability not only saves time, but it also minimizes damage to the underlying surface, ensuring that the subsequent installation of new flooring is seamless and efficient. With their adaptability and precision, oscillating tools are becoming indispensable in the toolkit of every DIY enthusiast and home improvement professional.

Oscillating tools have emerged as versatile instruments that can cut, sand, scrape, and shape materials with impressive precision. Ideal for both professional tradespeople and DIY enthusiasts, these tools excel in intricate tasks that demand a steady hand and accuracy. When it comes to cutting, oscillating tools can easily go through wood, drywall, metal, and plastic, allowing users to make clean cuts in tight spaces and awkward angles that traditional saws struggle with. This adaptability makes them perfect for home renovations, crafting, and detailed artistic projects.

When using oscillating tools, selecting the right attachment is crucial for achieving the desired results. For example, a wood blade is ideal for making precise cuts in timber, while a metal blade should be used for cutting through metal surfaces. Always ensure that the tool is securely held during operation to maintain control and prevent any accidents. Additionally, it's beneficial to practice on scrap material to get a feel for the tool and technique before tackling a main project.

For shaping materials, oscillating tools can effectively sand surfaces to perfection, allowing you to smooth edges or finish surfaces with ease. Use a finer grit sandpaper attachment for delicate tasks to avoid removing too much material at once. Remember to keep the tool moving to prevent overheating and damaging the material. These tools can also assist in removing old paint or finishing, making preparation for new layers easy and efficient. With the right techniques and tools, oscillating tool users can achieve professional-level results in their projects.

Oscillating tools have gained popularity in various DIY and professional applications due to their versatility and efficiency. One of the standout uses for these tools is sanding, which can significantly improve the quality of finishes in woodworking and home improvement projects. According to a report from the American National Standards Institute (ANSI), the right sanding equipment can reduce surface preparation time by up to 50%, allowing users to achieve a smoother finish while minimizing manual labor. The oscillating motion of these tools provides an even and controlled sanding action that can reach tight corners and intricate details that traditional sanders might miss.

When employing oscillating tools for sanding, it’s crucial to select appropriate sandpaper grits tailored for specific tasks. For example, beginning with a coarser grit can help eliminate imperfections, while transitioning to fine grits enables a polished finish. Data from the U.S. Bureau of Labor Statistics indicates that professional contractors who utilize oscillating tools report higher customer satisfaction rates, largely due to the speed and precision offered by these tools. Additionally, since oscillating sanders produce less dust compared to their rotary counterparts, they promote a healthier work environment, making them a preferred choice in many restoration and renovation projects.

This chart illustrates the efficiency of oscillating tools for various tasks, showcasing their versatility in achieving smooth finishes through effective sanding techniques.

Oscillating tools are becoming increasingly popular in the DIY and professional renovation markets due to their versatility and time-saving capabilities. According to a report from the Freedonia Group, the demand for oscillating tools is expected to grow at an annual rate of 5.3% through 2026, highlighting their rising importance in creative repair solutions. These tools can handle a variety of tasks such as sanding, cutting, and scraping, making them an invaluable asset for both intricate and large-scale repairs.

One of the most significant advantages of oscillating tools is their efficiency in tight spaces and awkward angles where standard tools might struggle. For instance, when dealing with trim removal or precision cutting of materials, an oscillating tool can significantly reduce the time spent on tasks compared to traditional methods. A study by the Home Improvement Research Institute found that users reported a 30% decrease in project time when using oscillating tools for home repairs. This efficiency not only saves time but also minimizes labor costs, making it an economically viable option for contractors and homeowners alike.

Furthermore, oscillating tools facilitate creative repairs by enabling users to tackle various materials, from wood to metal to plastic, without the need for multiple devices. This adaptability allows for more innovative solutions in repairs, enhancing project outcomes. As the industry continues to recognize the potential of these tools, their applications will likely expand, further establishing oscillating tools as a staple in both professional and DIY environments.

| Use Case | Description | Time Saved | Skill Level |

|---|---|---|---|

| Cutting Drywall | Easily cut drywall for repairs or installation. | 30 minutes | Beginner |

| Removing Grout | Efficient way to remove old grout between tiles. | 1 hour | Intermediate |

| Sanding Corners | Reach tight spaces and corners that sanders can't. | 20 minutes | Intermediate |

| Installing Baseboards | Cut baseboards quickly and neatly for installations. | 15 minutes | Beginner |

| Floor Tile Cutting | Make precise cuts on floor tiles for fitting. | 45 minutes | Intermediate |

| Plunge Cutting | Create openings in wood or drywall with precision. | 25 minutes | Advanced |

| Flush Cutting | Trim pipes or wood flush to surfaces. | 20 minutes | Intermediate |

| Rasps for Wood Shaping | Shape and smooth wood surfaces quickly. | 30 minutes | Intermediate |

| Paint Removal | Remove paint from surfaces efficiently. | 1 hour | Intermediate |

| Creating Outlets | Cut into walls to create new electrical outlets. | 1 hour | Advanced |

When using oscillating tools, safety should always be the top priority. These tools, known for their versatility, come with a range of enhanced safety features that can help minimize the risk of accidents. Many modern oscillating tools are equipped with protective guards, anti-vibration handles, and automatic shut-off mechanisms that activate in case of sudden drops or misuses. Additionally, the design of many blades has been optimized to reduce kickback, providing users with more control during operation. To fully leverage these safety features, it is essential to read the user manual and understand the specific mechanisms in place.

Best practices for oscillating tool use also play a crucial role in maintaining safety and ensuring effective outcomes. Before starting any project, it is imperative to inspect the tool thoroughly, checking for any loose parts or wear. Always wear appropriate personal protective equipment, such as safety goggles and gloves, to protect against debris. When operating the tool, maintain a firm grip and a stable stance, ensuring that the workpiece is securely clamped if necessary. Moreover, it is wise to familiarize yourself with different blade attachments and their specific applications, as this knowledge will not only enhance safety but also improve the quality of your work. With the right precautions and practices, oscillating tools can be safely utilized for a wide variety of tasks.